Hi all,

I am a noob to CNC and my Nomad and am trying to prototype a piece for work. I’m struggling with a design element. Anyone have advice?

The final piece is an 8" x 3" phone cradle made in a rubber-like plastic (see 1st pic of what we are imitating). I’m trying to generate a file that can be provided to a manufacturer who will make a mold and fabricate the pieces. Making an STL of the basic cradle in Inventor was easy enough. The element causing difficulty is a logo which should end up raised up from the surface like the IPC is in the pic. Instead of IPC there should be a globe there, raised only about .05"/120mm off the surface of the part.

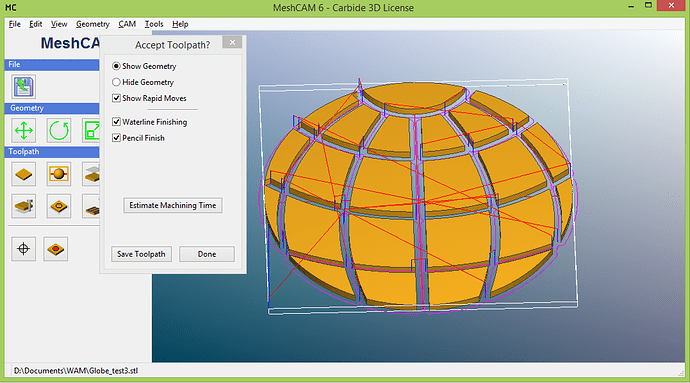

I made the globe as a separate part in Inventor and wanted to export it to STL to open in MeshCAM and mill it on the Nomad in RenShape just to see if it looked OK. If it does, I’ll put it onto the larger part. The diameter of the globe is only 2" / 50mm so it’s small. The groves are .08" wide and the plan was to use a .0625" bit. I also have a .0312", both are ball (MeshCAM wizard recommended flat). MeshCAM keeps returning paths that don’t show any cutting for the grooves and the time to completes are <1 minute.

Any thoughts on why it won’t generate a working toolpath or advice on what to try?

Thank you,

Brendan