Sure, I agree, could be easier, but this isn’t an “impossible” task. It’s really unclear why they don’t provide an easy provision (or for that matter, include one), but it’s what they do.

Do you know what caused the error?

Can you be more specific about what happened?

Grbl 1.1f [’$’ for help]

$$

**** Connected to /dev/tty.usbmodem641 @ 115200 baud ****

[MSG:’$H’|

Grbl 1.1f [’$’ for help]

$G

$$

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

$0 = 10 (Step pulse time, microseconds)

$1 = 255 (Step idle delay, milliseconds)

$2 = 0 (Step pulse invert, mask)

$3 = 2 (Step direction invert, mask)

$4 = 0 (Invert step enable pin, boolean)

$5 = 0 (Invert limit pins, boolean)

$6 = 0 (Invert probe pin, boolean)

$10 = 255 (Status report options, mask)

$11 = 0.020 (Junction deviation, millimeters)

$12 = 0.010 (Arc tolerance, millimeters)

$13 = 0 (Report in inches, boolean)

$20 = 0 (Soft limits enable, boolean)

$21 = 1 (Hard limits enable, boolean)

$22 = 1 (Homing cycle enable, boolean)

$23 = 0 (Homing direction invert, mask)

$24 = 100.000 (Homing locate feed rate, mm/min)

$25 = 2000.000 (Homing search seek rate, mm/min)

$26 = 25 (Homing switch debounce delay, milliseconds)

$27 = 5.000 (Homing switch pull-off distance, millimeters)

$30 = 1000 (Maximum spindle speed, RPM)

$31 = 0 (Minimum spindle speed, RPM)

$32 = 0 (Laser-mode enable, boolean)

$100 = 40.000 (X-axis travel resolution, step/mm)

$101 = 40.000 (Y-axis travel resolution, step/mm)

$102 = 320.000 (Z-axis travel resolution, step/mm)

$110 = 5000.000 (X-axis maximum rate, mm/min)

$111 = 5000.000 (Y-axis maximum rate, mm/min)

$112 = 1000.000 (Z-axis maximum rate, mm/min)

$120 = 400.000 (X-axis acceleration, mm/sec^2)

$121 = 400.000 (Y-axis acceleration, mm/sec^2)

$122 = 400.000 (Z-axis acceleration, mm/sec^2)

$130 = 120.000 (X-axis maximum travel, millimeters)

$131 = 850.000 (Y-axis maximum travel, millimeters)

$132 = 80.000 (Z-axis maximum travel, millimeters)

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

Grbl 1.1f [’$’ for help]

$$

[MSG:’$H’|’$X’ to unlock]

$0 = 10 (Step pulse time, microseconds)

$1 = 255 (Step idle delay, milliseconds)

$2 = 0 (Step pulse invert, mask)

$3 = 2 (Step direction invert, mask)

$4 = 0 (Invert step enable pin, boolean)

$5 = 0 (Invert limit pins, boolean)

$6 = 0 (Invert probe pin, boolean)

$10 = 255 (Status report options, mask)

$11 = 0.020 (Junction deviation, millimeters)

$12 = 0.010 (Arc tolerance, millimeters)

$13 = 0 (Report in inches, boolean)

$20 = 0 (Soft limits enable, boolean)

$21 = 1 (Hard limits enable, boolean)

$22 = 1 (Homing cycle enable, boolean)

$23 = 0 (Homing direction invert, mask)

$24 = 100.000 (Homing locate feed rate, mm/min)

$25 = 2000.000 (Homing search seek rate, mm/min)

$26 = 25 (Homing switch debounce delay, milliseconds)

$27 = 5.000 (Homing switch pull-off distance, millimeters)

$30 = 1000 (Maximum spindle speed, RPM)

$31 = 0 (Minimum spindle speed, RPM)

$32 = 0 (Laser-mode enable, boolean)

$100 = 40.000 (X-axis travel resolution, step/mm)

$101 = 40.000 (Y-axis travel resolution, step/mm)

$102 = 320.000 (Z-axis travel resolution, step/mm)

$110 = 5000.000 (X-axis maximum rate, mm/min)

$111 = 5000.000 (Y-axis maximum rate, mm/min)

$112 = 1000.000 (Z-axis maximum rate, mm/min)

$120 = 400.000 (X-axis acceleration, mm/sec^2)

$121 = 400.000 (Y-axis acceleration, mm/sec^2)

$122 = 400.000 (Z-axis acceleration, mm/sec^2)

$130 = 120.000 (X-axis maximum travel, millimeters)

$131 = 850.000 (Y-axis maximum travel, millimeters)

$132 = 80.000 (Z-axis maximum travel, millimeters)

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

$X

[MSG:Caution: Unlocked]

ok

Skipping comment-only line: (%)

Skipping comment-only line: (TOOL/MILL,0.1,0.05,0.000,0)

Skipping comment-only line: (FILENAME:)

Skipping line: ()

G21

G90

G0X0.000Y0.000Z0.000

Skipping comment-only line: (TOOL/MILL,3.1750,0,1.0000,0.0)

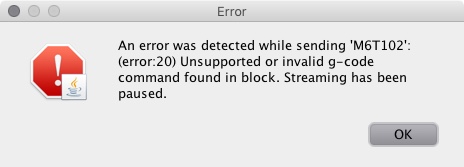

M6T102

M3S6111

G0X6.395Y295.650

G0Z0.000

G1Z-0.715F105.7

G1Y295.967F422.6

ok

X221.342

Y295.650

ok

X6.395

ok

X4.966Y294.221

Y297.396

An error was detected while sending ‘M6T102’: (error:20) Unsupported or invalid g-code command found in block. Streaming has been paused.

**** The communicator has been paused ****

**** Pausing file transfer. ****

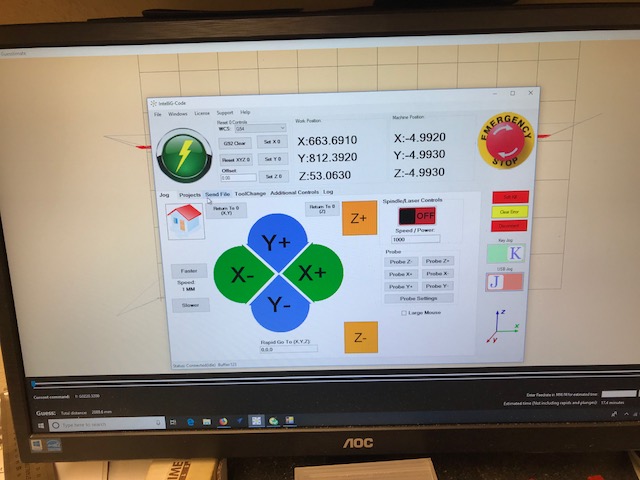

Another reason I like Intelli-G-Code by Software Redefined as a G-Code Sender

GRBL doesn’t support tool change commands (M6), and it looks like UGS doesn’t handle them for you.

I’m telling you, use CNCjs.

After that error the Z plunged though?

was this set to 120.ooo on purpose

Nope. What should it be? 406.400?

are you on an xxl? if so it should look like this

$130 = 845.000 (X-axis maximum travel, millimeters)

$131 = 850.000 (Y-axis maximum travel, millimeters)

$132 = 120.000 (Z-axis maximum travel, millimeters) im guessing 120.ooo for the new hdz. stock was 80.000

I’m running the SP3.

If only it woud run on a Mac

See the message I sent you enter the m6 command.

I think the spindle upgrade may have been a step beyond my capability as a CNC hobbyist. Will give it another day to see if I can figure everything out.

Considering purchasing MeshCam in hopes that it will export cleaners GRBL.

Also considering adding a 50 mm spacer between the HDZ and the Z hopes of avoiding having to unassemble my machine and start over.

Mr. Beaver any thoughts on how to implement the spacer? Adding a 50 mm spacer for the HDZ to your store might be a good product to add for those who are not ready to make the leap away from carbide create and carbide motion.

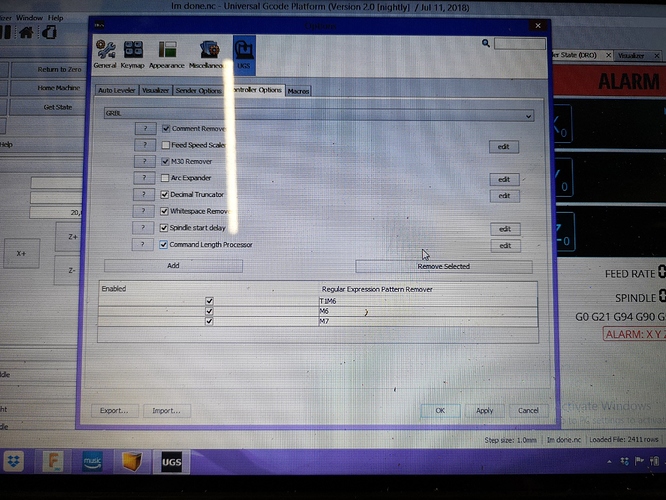

It’s a learning curve. I would say keen going. To use UGCS you need to add regular expression remover - Under preferences, UGS, Controller options there is a regular expression remover, enter the attached in it and you should be good to go.

If your still not keen might I suggest trying CNC JS - it’s a bit more user friendly than UGCS.

I doubt I could offer a 50mm spacer quickly. I could look into some kind of lower limit switch bracket that users could make themselves?

Got my machine up and running. Cut my first project today. One final issue is that y access seems to drift over time. I will run some more test tomorrow, but the cause seems to be UGCS. At the beginning of a new pass the spindle moves up and forward at an increasesed rate causing the machine to shake.

Made the same part later in the day using Motion with no drift in the y access.

Made the changes you recommended. Did the trick.

Got UGCS working today. Will try CNCjs tomorrow. Still trying to figure out probing in CNCjs.

We need to lower your rapid movement on x/y likely its set a little fast. 2000 i think is about right on a xxl

$110 X Max rate, mm/min

$111 Y Max rate, mm/min

$112 Z Max rate, mm/min

I’m running the SP3 16” (X), 16”(Y)… What would recommend setting the rapid movement at?