I repeatedly see the belt tightness being described as Guitar String Tight. Honestly, I have no idea what that means.

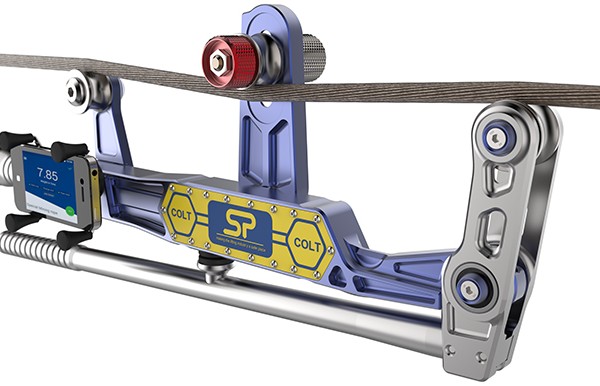

When tensioning a guy wire cable, one would use a tension meter which gives distance over unit weight, so 1mm/kg, for example.

I’ve been thinking that it should be fairly easy to come up with a belt tension device calibrated for our machines (not giving actual numbers, but just marked with the proper tension level) using a couple of sliding blocks connected by a spring, whereby tension should be less than a certain distance of play. I can’t, however, design such a device as I have no idea if my belts are tensioned properly. I’m concerned with over tightening the belts and bending the stepper motor shafts.

Since belt tension plays such an important part of keeping our machines running properly as it seems every post about z height issues, oblong circles, etc seems to come back to tightening the cables properly, would it be possible for someone at Carbide3D to come up with plans for such a device? Something users could cut and build themselves? Or sell on the website, or maybe a kit of the hardware needed.

For the x & y belts, the device would sit on the bar with the belt over a pin that can slide up and down. The spring would push or pull, depending on design, the pin upwards and the belt would be tightened down until the pin is pulled down to a set point. The z belt would take a little more thinking, due to space restriction, but I’m sure it could be done. Maybe two pins and measure the spread between the two belts?