I currently have the Dewalt Router for the XL and thinking about getting a water cooled spindle. What are the differences that I will see? Faster?

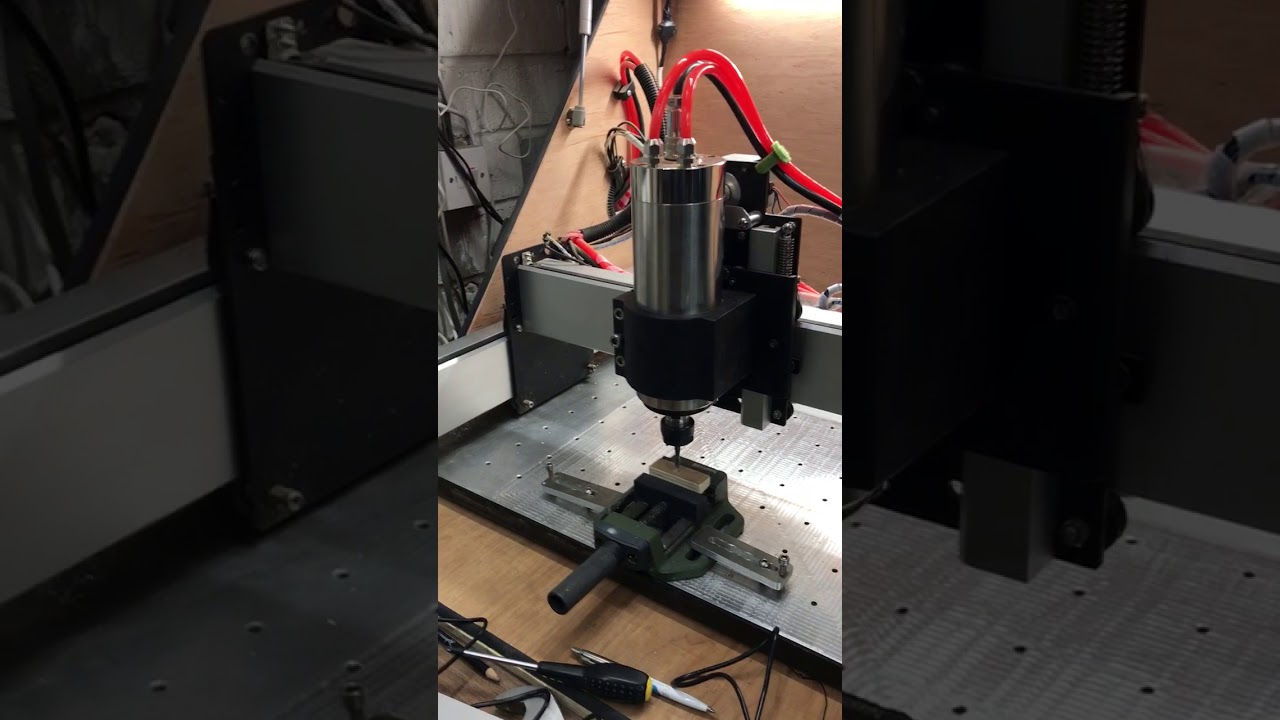

This might help you out

I have just ordered an XL and was also thinking already of a spindle upgrade.

If you go to the above “Luke” link and run the video at the bottom you can hear the horrible screeching sound of the spindle. It may be quieter in decibels vs a router but the tonal quality is really hard to listen to…

My question for anyone with a water cooled spindle is how does yours sound compared to Luke’s?

Recommendations for a quiet spindle?

Also, do they all have to run thru a VFD or can some use just a DC power supply?

I have read the wiki but didn’t come to any conclusions.

I’d say you were probably running before you can walk if you are yet to use your Shapeoko, unless your upgrading?

The dewalt works really well and taught me allot. I had my reasons for upgrading.

It is also allot quieter and from a tone point of view does sound different to the video. It’s incredibly quiet compared to the dewalt. The screech is not present when in use. See the later videos.

All spindles require VFFs

It must be the recording equipment because both of your 2.2 kw spindles have the same high pitched “screech” for lack of a better word. I couldn’t even listen to the whole video.

See this video at 6:15 in: https://www.youtube.com/watch?v=sAUYFsiuY-8

He runs the spindle at 23000 rpm and it sounds much better, like I hoped it would.

I have also heard a couple of 1.5kw spindles on youtube and they sounded pretty good so I’m going to chalk it up to the recordings.

Thanks for posting.

This. Spindle upgrades are great, but there are very few things you can do with a spindle on your shapeoko that it can’t do with just the palm-router motor. If you’re all in on wanting it quiet, build a good enclosure which will help far more than a spindle upgrade.

I’m not so much interested in the sound, I’m hoping to get faster cutting rates and be able to do aluminum. How much gain on feed rates?

You can cut al just fine with a router spindle. Faster cut rates compared to what? Why don’t you share your cutting speed and production requirements, then we can work backwards toward what will accomplish that goal.

I was just wondering the gains to upgrading to a water cooled spindle. If its just a noise change, I’m not interested but if I’m gaining faster speed and feed rates then it something to consider. Maybe I’m confusing the too…

In the shapeoko world, noise reduction is the ‘simple’ gain. The S3 is not a massively large professional CNC, nor is it priced as one. There is a reason it comes built to use a palm router and not a 3HP spindle motor - it’s simply not rigid enough to take FULL advantage of how fast and deep you COULD run a 3HP (2.2kW) spindle, if you were on a professional machine.

Again, if you give some examples of the type of work you’re wanting to run and your timing/production requirements (parts per day/hour, and drawings) then it’s pretty easy to work backwards to what sort of machine you need.

John

I need to thank you! I looked into this more and contacted the manufacture who advised on a VFD setting change. By doing so it’s now even quieter. PD041 makes a difference.

Thanks

Luke

Frequency Carrier… hmmmm Now I’d have to think about that. What wisdom did you get from the VFD folks, @Luke?

I know, I’m not sure I understand it. It was on setting 3 and they said change it to 8 - I did so and the note has dropped. I see this setting goes to 15, but I have no idea what 15 would do?

For what it’s worth, I spoke to my friend who is an Electrical engineer and he says we should avoid going over 6 on Carrier frequency as it can damage the spindle . He said it adds heat also but with the water cooled spindle it would probably have a minimal impact.

I set mine to 6 and it is better.

Good catch Luke!

It’s very interesting. I don’t really understand what it’s doing but I will keen an eye on it and my coolant temperature.

So is the real benefit just the sound? I ask because I use my XXL for production for my small and budding business and I am always looking for ways to improve production rates and such. Thanks in advance!

| • | Higher torque and lower speeds – better for milling aluminium and some wood |

|---|---|

| • | Much, much quieter – my ears are taking a much needed break |

| • | Greater selection of collets – allowing you to select more versatile end mills (more so in the UK) |

| • | Better accuracy and less run off |

| • | Less heat – meaning wood doesn’t warp when being milled |

| • | Less maintenance – no need to change bushings |

| • | Arguably cheaper in the long run… |

You get my vote for one of the best answers to a question