Ok, so I’m new to CNC. I purchased a Nomad 883 back in May and it arrived in mid June right before I was leaving for a 1 week trip. I unboxed it, and found it a nice home on it’s own desk in my office. While traveling, I got all of the software loaded onto my machine so that I would be ready to go when I returned. I even got started on a few projects in Fusion 360. When I returned home, I was so excited to make my first project. I started with the wrench project that is part of the Nomad new users tutorials. I had no problem loading and running the files, but the double sided sticky tape did not hold and the cut was unsuccessful. The second time I tried it, the material stuck down good…too good. The wrench bent when removing it from the table. Not a perfect start, but not bad either. I wasn’t interested in the wooden sign or the 3D figure, so on to my projects.

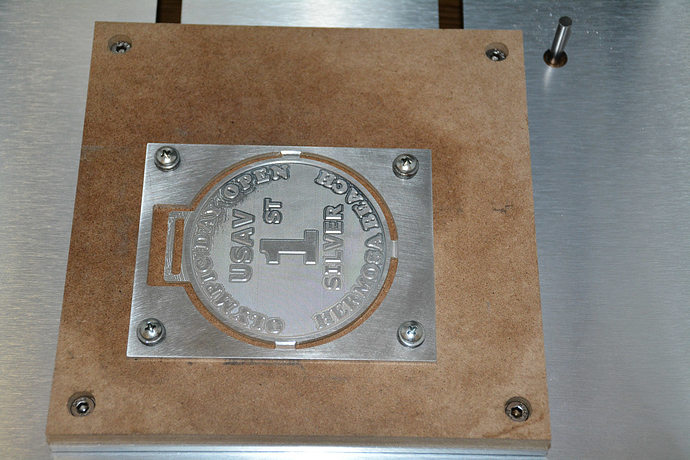

I designed a awards medal in Fusion 360 with plans of cutting it out of 1/8" aluminum plate. After completing the CAM setup and configuration, I i exported the .nc file using the Post Processor function in Fusion 360 using the carbide3d.cps config option. The file is quite large at 160K lines of G-code.

I loaded the file in Carbide Motion, set the out the zero point of the material stock and started the cutting. About 30 minutes into the process, the Nomad 883 stopped cutting (spindle was still rotating) and the following error was displayed in Carbide Motion, GRBL Error: Invalid gcode ID:33

I paused the job and tried to continue with no luck. I restarted the job and ran it again with the same result. The error happens about 30 minutes into the job or about 12% through according to Carbide Motion. After reading the forums and changing parameters in Fusion 360 and doing a new .nc Post Process, I continue to have the same issue. I can’t seem to identify what the issue is.

After hours and hours of no luck, I decided to give bCNC a try. It was a little cumbersome to get installed and working, but I have it connected to my machine and I can jog the mill and turn on and off the spindle. I just cant seem to get it to run the g-code file. The file loads fine, and displays properly on the preview screen. It just wont execute the g-code. When I hit play, the Nomad 883 jog’s a few mm and then stops. The spindle never starts, and the tool length is never checked. I’m certain that I don’t have some of the configuration settings right for the 883, but I can’t seen to find out any details on the step by step setup of bCNC for the Nomad.

I eventually want to get bCNC on a Raspberry Pi 3, but for now, I just want to get the thing working from my PC. I’m stumped and don’t know where to turn next. I didn’t want this to be my first post in the forums, but I’m out of options. The wife is questioning why I spent the money on this thing, if I can’t even get it to work. I need some help fellow Nomad users.

Sincerely

Allen

PS - Here is the .nc file that I am trying to run if anyone is interested.

ODO Medal Final R2.zip (902.4 KB)