I am assembling my Shapeoko XL and the limit switch on my x-axis appears useless because of the drag chain comes out toward the right (looking from the front) and loops back to the left to where the control box is. The X/Y bracket stops moving to the right because the drag chain binds up. The limit switch is no where close to the end bracket.

Usually this can be adjusted by loosening the hardware in question, pulling it into the desired alignment, then tightening it, sometimes slightly bending the drag chain bracket up will help. One option is to only use one screw in the rearmost hole on the bracket and the frontmost on the drag chain. Some folks have found it helpful to put a couple of washers under the drag chain bracket to push it out into a better alignment (the drag chain should slightly hang off the rear of the extrusion), other solutions include sourcing a longer drag chain bracket from the hardware store, or placing a piece of angle on the extrusion to guide the drag chain.

A straight-forward solution is to only use one hole (rearmost on bracket, nearest on drag chain).

thanks for the options

I just recently posted about this while building my XXL.

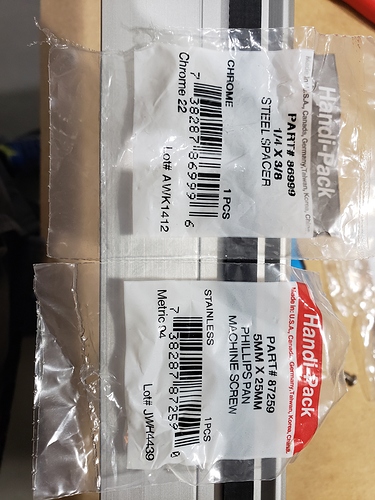

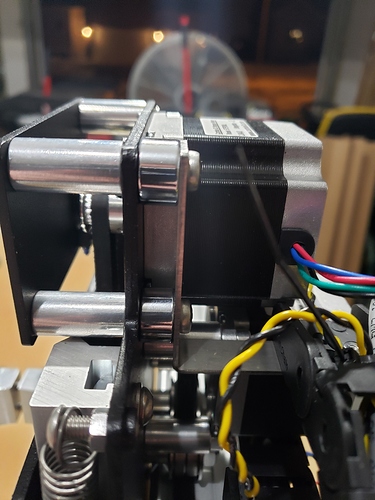

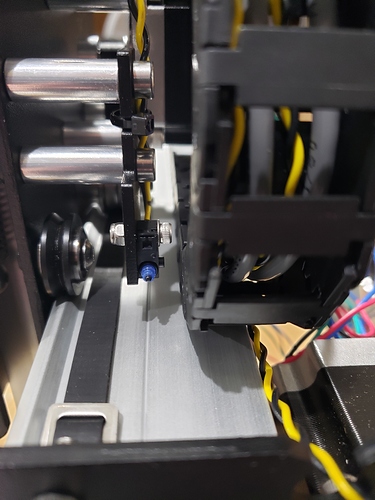

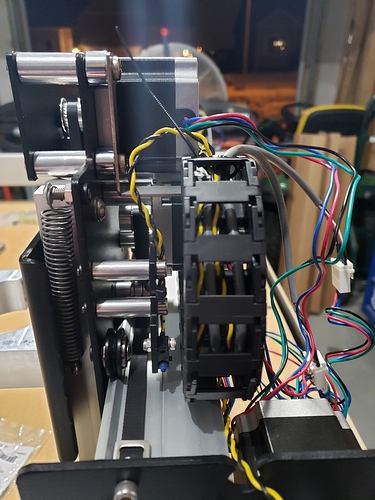

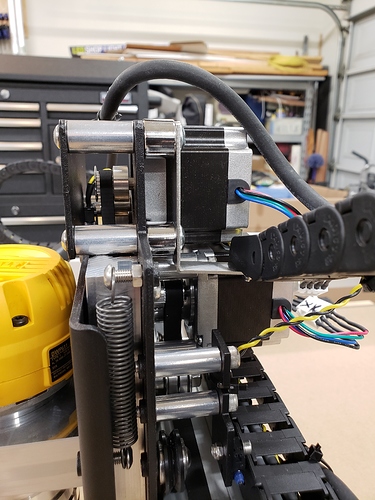

I went the route of adding two spacers in between the drag chain bracket and the X/Z axis plate as shown in the picture in this thread:

http://community.carbide3d.com/t/x-axis-limit-switch-interference/12008

I used a strip of glued-on 1/2in foam insulation used for doors and windows on the top of the extrusion, it gently pushes the drag chain so it stays at the back of the extrusion. I had tried adjusting using the screw but it was not consistently staying at the right place but now stays where it needs to be.

Okay. Your setup looks sweet. I will play around with the other options but I am leaning toward this solution.

While I am on the topic of drag chain. approximately how far from the left end plate (looking from the front) should the end of the x-axis drag chain end? Same for the y-axis drag chain. How far from the back end plate should the end of the chain be secured? I know there will be variance but I am just looking for an estimate to help me make sure all the wires are where they need to be.

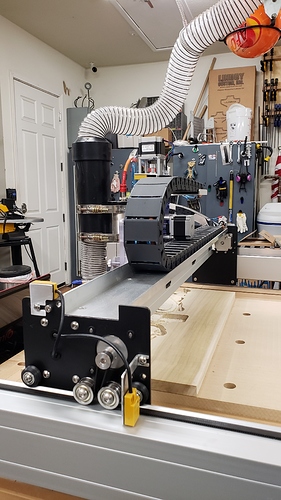

A photo which may help:

Best thing to do is to move the machine to the far end, then pull the drag chain tight, then push it back a bit to allow a bit of slack.

I removed the limit switch from the mounting bracket and reinstalled it on the other side of the mounting bracket. That solved the issue. It now hits on the small mounting clip that holds the timing belt but it does work.

Thats why i went with spacers. Not sure if contacting the belt bracket will cause damage to the switch.

I used Erik’s suggestion of using the spacers and it is a thing of beauty. for the couple bucks the additional spacers/bolts cost it was well worth it to me to keep the setup as close to documented as possible.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.