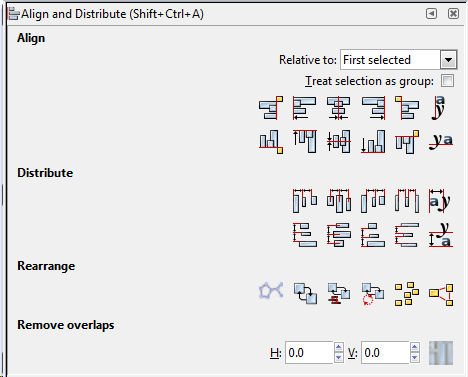

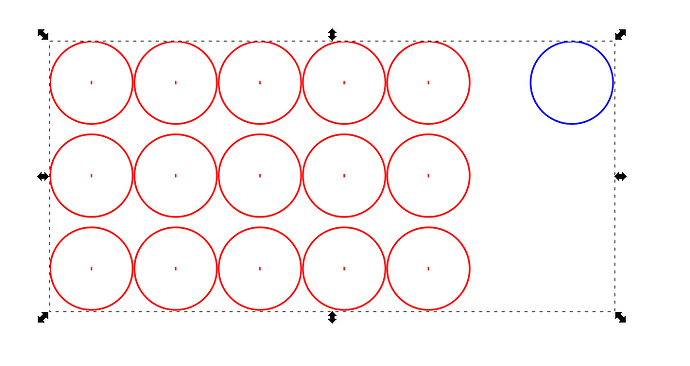

For me, making cribbage boards is all about nice straight lines of holes, so it’s all about this group of icons:

And also learning how using [CTRL] and [SHIFT] affect what you select when clicking on an object.

[SHIFT] + [LEFT MOUSE BUTTON] lets you select multiple objects or grouped objects. Press and hold [SHIFT] and left select as many objects as you want one at a time. You can also un-select objects as well. while holding [SHIFT].

[CTRL] + [LEFT MOUSE BUTTON] lets you select a single object - even if that object is part of a grouped object. For example: If you have a group of 5 objects grouped together, selecting any one object in the group using [LEFT MOUSE BUTTON] selects the entire group. Using [CTRL] + [LEFT MOUSE BUTTON] selects only that one object you clicked on.

And using the [LEFT MOUSE BUTTON] and dragging a bounding box only selects objects that are COMPLETELY WITHIN THE BOUNDING BOX, which is helpful later on.

Okay, I start with a circle - for 1/8" pegs, I use a 1/4" circle for spacing the holes. Then I put in a small line and center it both vertically and horizontally and group them together.

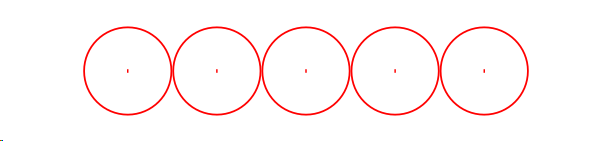

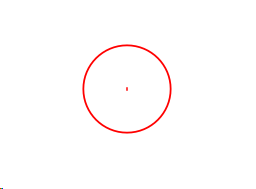

Then, to make the 5 holes for the group I use the “Align to the right or the selected object”  button. Once that is done, I group them together [CTRL] + G

button. Once that is done, I group them together [CTRL] + G

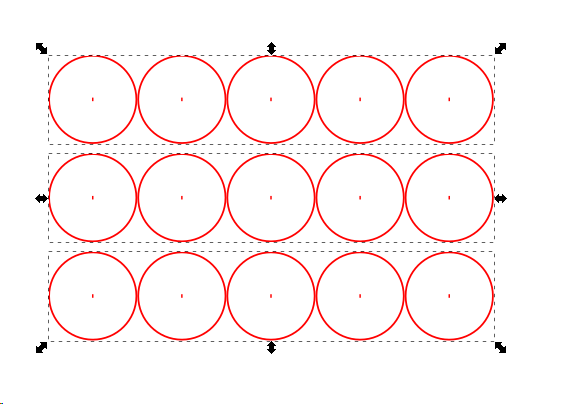

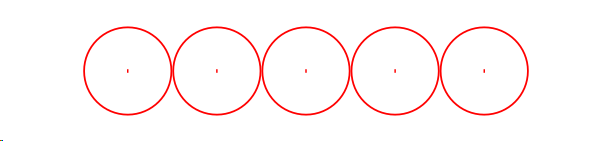

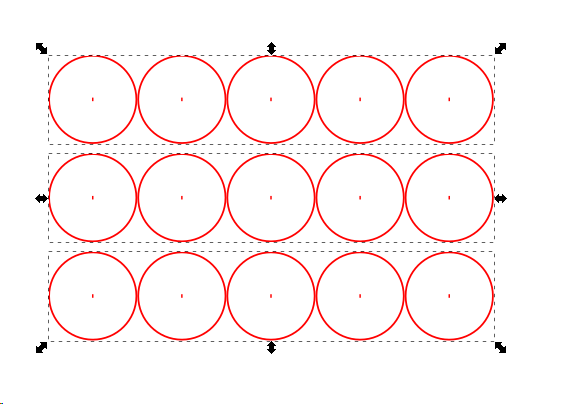

Now, depending on how many players the board is going to be, I add the additional rows for each player. Let’s make a 3 player board. Here they are, still selected. I add some spacing between the runs to make it easier to grab the pegs.

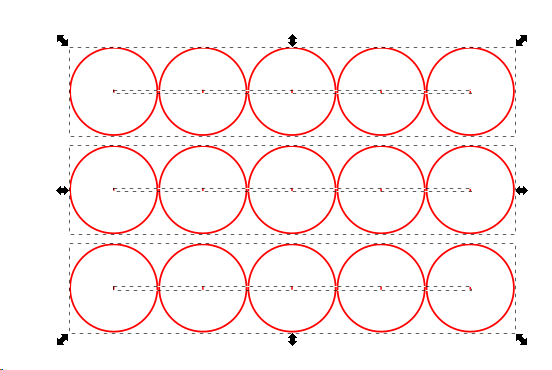

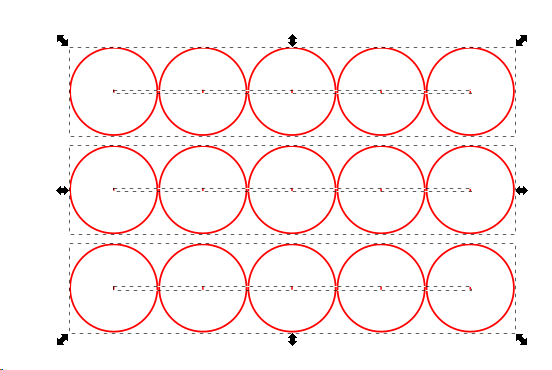

Now I un-group everything using [CTRL] + [SHIFT] + G and re-group the circles in each run separately from the lines in each run.

Then I group the lines together and the circles together. Then I group the groups of lines and groups of circles.

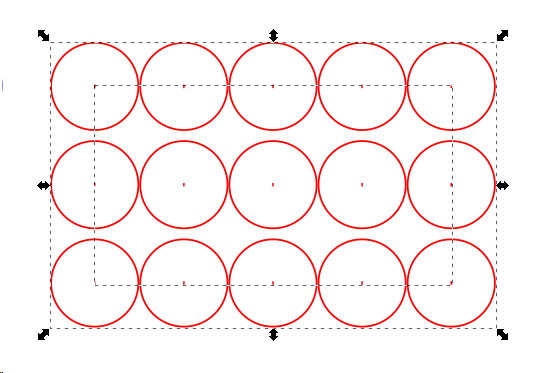

Then finally group the two groups together.

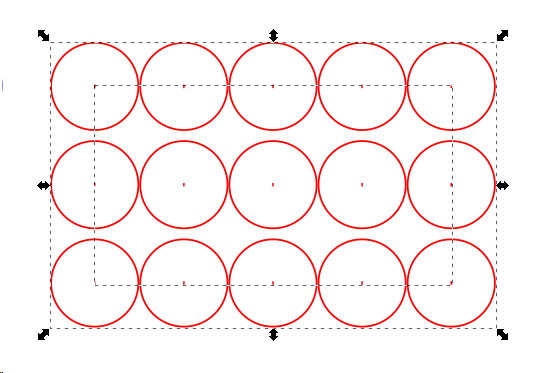

Now, I need to determine how much room to put between each block of 15 holes. I find a good distance that looks nice and put a circle out there, and change its color and group it with the previous group.

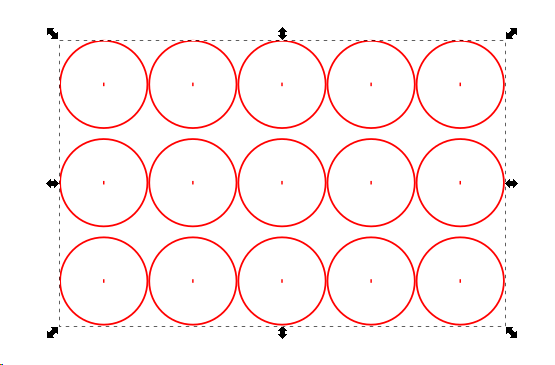

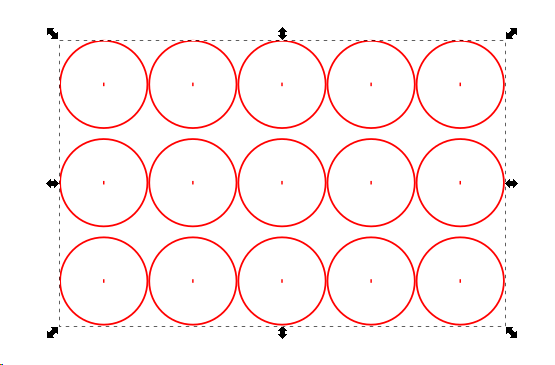

OKAY! Now we have our basic block of holes, all lined up and ready for duplication and alignment.