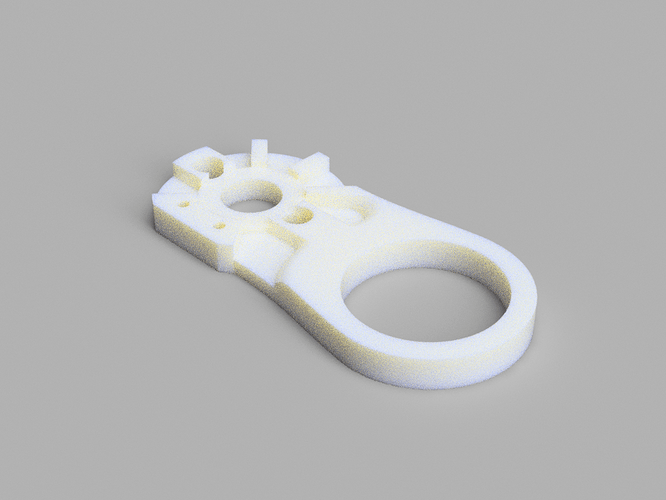

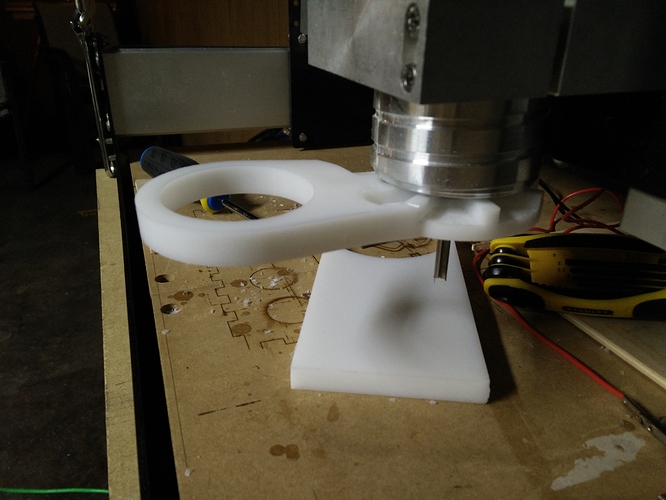

Well this is the first 3D milling ever done on any CNC machine. The exhaust diverter works perfectly. The screw holes line up with the stock Dewalt screws, but require 1/2" thicker. Still need to mill the bottom attachment, holding the brush.

Elegant!

Kind of bummed that (going by memory) my Makita doesn’t have similar screw holes — I don’t think anyone else has used them for this — surprised.

Files?

VERY NICELY DONE!

Do you have plans for a skirt or brush? I don’t see places for magnets (the common solution) so it will be interesting to see how you’re going to approach the skirt/brush.

General design guideline. The skirt brush must be as far away from the tool as the height of the brush - otherwise the brush gets eaten (but they tool).

mark

awesome!

have you tried/thought about PMMA so you can see the cutting tool while machining?

cheers, mate!

The dust shoe files are available for purchase.

Also if you would like to purchase the assembled shoe.

1 Like