Slicers are fairly simple geometrical programs. CAM is MUCH MORE complex.

The CAM you’re seeing here is… primitive to say the least compared to High Speed Machining and more than 3 axes. The software to handle high end CAM is wickedly complex and in a somewhat limited market.

CAM is not just about geometry, it’s about materials, physics, lubrication and cooling, finishes that are accurate/precise to tiny factions of an inch, adapting to power and torque curves and many other things.

Advanced CAM - like High Speed Machining - are beyond what a human can handle - dozens of factors being solved in parallel and constantly adjsuted. Multi-axis - in trivial conditions - is human solvable but serious machining is now way beyond what a human can do (at least in reasonable time).

By-the-by real businesses cannot afford to deal with a product that is buggy or cannot be supported quickly. They are willing to pay to get what they need. Even to the point of $$$… because they get what works for them at a cost they are happy with. In many shops, a $15K (or even $30K) CAD/CAM package makes perfect sense - it saves many minutes of machining time per piece, makes tools last longer and produces finer finishes. They can call and get someone who understand complex machining details and get things fixed quickly.

Shops that have invested decades of learning and training do not simply jump to the latest and greatest neat package. They can easily go out of business if they did. Training and ensuring there are no bugs in their work flows is SERIOUSLY COMPLEX. They stick with what they know and what works for them.

The cost of a package isn’t a simple inducement, even if it is 10X cheaper. They have work to do. The software packages know this and the “lock in” - due to complexity, support, FUD, specialized strategies - slows changes.

I’ve got many thousands of $ invested in CAD and CAM programs, packages I’ve used for years. I’m not about to jump until I THINK I see something that may work at a price significantly less than what I pay per year to keep what I know inside and out running AND I can afford to spend weeks and months trying out my old projects AND am satisfied that the quality is there. PAIN… it’s got to be worth it.

Much of the CNC market is 2.5D and this is well served with many packages (e.g. Carbide Create, Vectric Cut2D/VCarvePro, SheetCAM, CamBam) - at low cost - even for professional shops (e.g. wood working). There is some open source too.

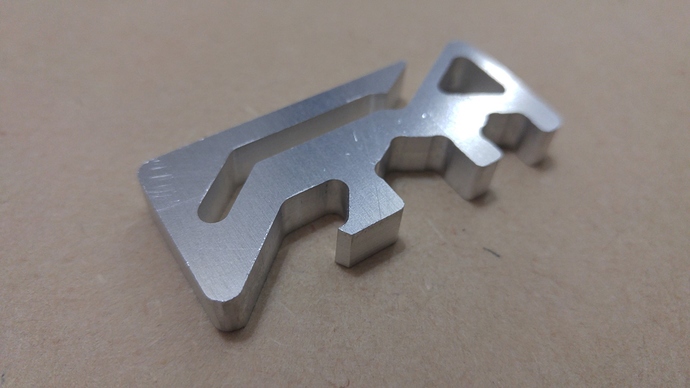

MeshCAM is essentially a 3D CAM program…

The home market and small CNC machines added amazing hardware at accessible prices; the software is largely unchanged. MeshCAM - and the Nomad - are one of the first successful efforts to try and bring the software quality at prices appropriate to the home and small CNC market.

Open source efforts to do CAM have largely been limited to the simple stuff. Limited users and no reason to cooperate. Companies have spent decades perfecting their software and only recently started to deal with the reality of the WEB, small machines, serious numbers of users with limited budgets and so on (e.g. Fusion 360).

IMHO, the 3D printing craze siphoned off a great deal of the talent that was in or heading to CAM and those efforts have taken a back seat. I do hope this all changes, especially as people are discovering that the low end 3D printers are limited, especially in finish quality and durability (things are improving though).

Over time, we’ll see things “loosen up” but it’s not going to happen for a bit. Fusion 360 is SUPERB and a fine example of where things should head. It’s way below what I can use - it lacks 4 and 5 axis machining along with many of the machining strategies I expect - but it’s getting close QUICKLY. I highly recommend that you take a look… I’m pretty sure you’ll be very happy (after you get over the learning curve).

mark

hacked

hacked