Hey gents - I need some help

Issue - no idea how to create (2) files - please see below.

Equipment:

Shapeoko XXL

3/4" Bottom Cleaning Bit

What I’ve done so far:

I copied the XXL waste-board kit from the online Carbide store with locally sourced track and MDF I had on hand. My waste-board covers the entire deck, which I’ve learned will leave a ‘ridge’ marking the X/Y boundaries one I run the levelling function.

To eliminate this, it was suggested that I run a 32"x32" ‘square’ in Carbide Create to give me a thin outline as reference. From there, unscrew my existing waste-board and then trim off the ‘out of bounds’ area with a table-saw, re-mount to my XXL base and then run a levelling function.

I’m guessing that this will take 2 separate files in Carbide Create - one to mark the perimeter with a light pass and another for the actual levelling process once I have my waste-board trimmed and reinstalled.

-

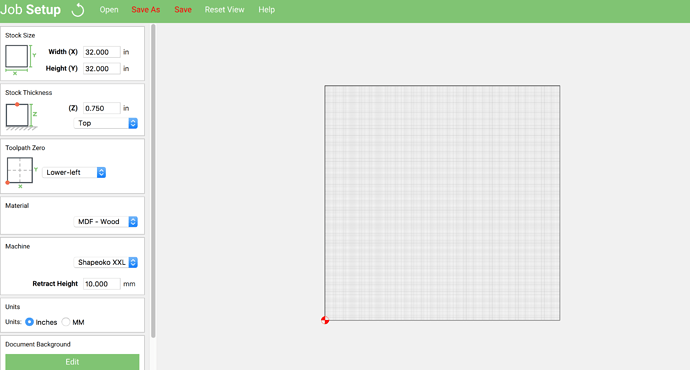

For the first operation (perimeter cut), I’ve created a new file in Carbide Create setting ‘stock size’ to 32 x 32.

-

For ‘stock thickness’ I set it to .75 (3/4" MDF) - dropdown is set to ‘top’ but I don’t know if this is right.

-

Toolpath Zero - set to ‘Lower Left’

-

Material - set to MDF-Wood

-

Machine set to SH. XXL - ‘retract Height’ set to default 10mm (no idea if this is suitable / what this means).

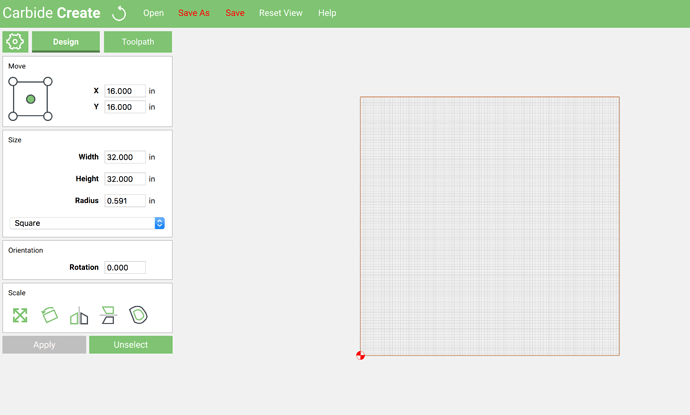

Then I created a rectangle at 32 by 32, X/Y are set to 16".

This is as far as I’ve gotten. I have no idea what to enter in the ‘Toolpath’ tab or how to run the next file for actually levelling the board.

I appreciate any help. ‘Dumbing down’ is highly encouraged. Thanks!!