I just got my Shapeoko 3 XXL and am still learning how to do stuff. I’m wondering if this is possible in Carbide Create. I want to cutout the shape of Wisconsin so that it’s only a 1/4" outline (i.e. - cut it out on the outside and then get rid of the inside - leaving just a 1/4" thick outline that’s 3/4" deep). I figured out how to do this part; just created and offset. The part I’m struggling with is I want to put some text inside (sitting on the bottom portion of the state) and join that together. I can’t figure out how to join the text with the 1/4" outline. I’ve tried all the boolean union functions and doesn’t seem that those would work unless I wanted the text outside of the state outline. Is this possible? Hopefully my description made sense.

One way to do this would be to:

- offset the outline of the state by 1/8" both to the inside and the outside

- set the text on the inside

- select the inner outline and the text and cut that as a pocket

- then cut the outer profile

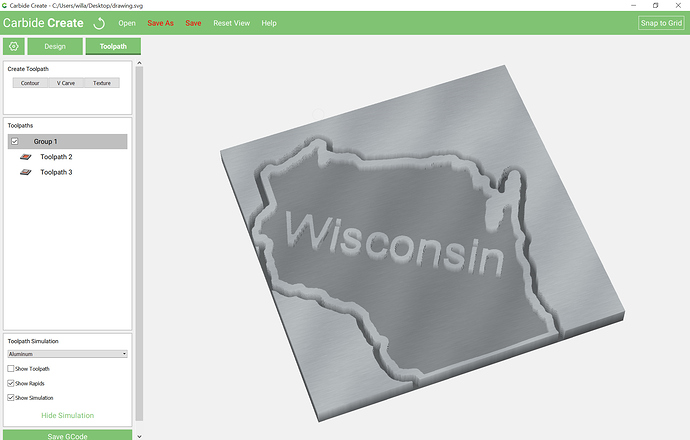

It should look like this:

Attached:

wisconsin-text.zip (289.0 KB)

Thanks Will! That worked for the most part (other than some font issues - seem to be be having trouble with it not cutting out part of letters that it should; anyway, hopefully I can figure that out).

I do have one un-related newbie question. Is there a way to create efficient toolpaths? By this I mean, I just cut my first sign and it turned out great; however, it was extremely inefficient. I started with a toolpath for 1/4" straight cut bit; that cut-out most of the sign really quickly (25 min or so). And then I figured I’d create a toolpath for an 1/8" bit to get the details on inside corners of letters, etc… Unfortunately, the 1/8" bit re-cut the entire pocket and took forever (maybe 3.5 hours). 95% of the time it wasn’t even cutting. I’m assuming I missed something in the SW. There must be a way to tell it what material is already gone when creating the path for the 1/8" bit. Thanks again.

What you want is called “rest machining” and unfortunately, Carbide Create doesn’t have direct support for it.

You can use offsets to define regions which you cut and then cut spaces which they don’t cut, but this can be risky since a mistake can snap a smaller tool — the concepts are shown in: Adding geometry to cut as a pocket with a finishing pass

Similarly, Carbide Create doesn’t deal well w/ multiple pockets — there are third party tools which may be able to optimize the paths, or you can select one pocket at a time to generate toolpaths.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.