So I’ve been cutting aluminu dry forever. And sometimes it works well but sometimes it’s terrible. A friend recommended isopropyl alcahol and it’s made a crazy difference. I cut mirror finish passes every time! The only issue is that I have to stand there and squirt it. Also it’s not extremely good for you. Does anyone have a setup for lubing aluminum that doesent require me to stand there, doesn’t ruin my bed, and works As well? Extra points for safe lol

Thats interesting. I hadn’t heard of that being used. Any pictures?

Personally I use water soluble oil similar to this:

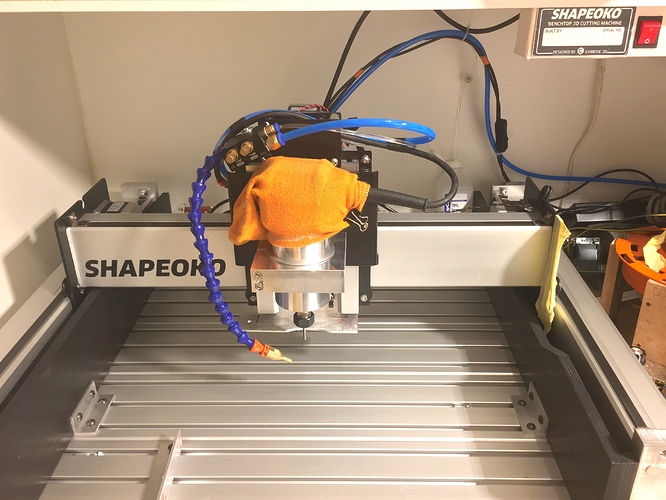

I’ve just had one of these come for this very reason:

You do need to hook it up with a compressor. I’m also considering hooking mine up to a garden style pump action weed sprayer so I don’t have to wire a direct feed to my compressor.

@RichCournoyer has a excellent hack using a old WD40 can

The “traditional” way is to use kerosene. It works pretty good, but it’s stinky and messy.

This is one of those good reasons to use HDPE or aluminum for a wasteboard.

With even “drop” cast aluminum going to $5/lb, it gets kinda spendy though.

I have been using 70-90% alcohol with success since January. No explosion yet in the encosure as some folks predicted

I run a Hyundai Silent oil free air compressor that is produced and sold under many brands. This particular model makes 135 l/min at 8 bar and has a 24 l tank. Unfortunately it is not designed for continuous use and it got really hot sometimes. To prevent overheating I put it right under the exhaust fan of my enclosure and it keeps it around 40-45 celsius.

The sprayer operates around 2 bar and makes a little bit of mess, that is why I have the chip guards and a piece of tape protecting the rails. This is a quick and dirty solution! My coolant spray doesn’t moves up and down with the router but still does the job.

My sprayer is permanently connected to the compressor to prevent any dirt entering the air system and clogging the needle valves or the nozzle. I put a ball valve under the table to turn it on and of rather than disconnecting the hose from the compressor.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.