that’s actually the best idea I think I’ve heard so far, I think I need to draw something up  Cheers Barry, something like that could really work here in the tourist shops. I’m in Auckland. Regards wealthy try this.

Cheers Barry, something like that could really work here in the tourist shops. I’m in Auckland. Regards wealthy try this.

Auckland house prices are over 1mil on average!

We just had a the Ovation of the Seas cruze ship come into the harbour (it actually came to Dunedin first I think) and the spend by the passengers was around 1.5mill in the aprox a week it was here. Someone has to get that spend. Why not us instead of Louis V and Prada.

As for the rest of the country dairy is back on track. Sure we are no switzerland but we’re still bloody lucky compared to most of the poor sods in the world.

So you got a shapeoko or a nomad?

Hi Leith ,My parts for mine came from NZ Kits, Auckland they are open builds I pinched quite a bit of his ideas, off Metal guru, I really liked his set up, out of all the ones I looked at has work area of 480mm x480mm,ill try get some photos up of it,they are all in my phone, so I need get them up asp

Okay, so I couldn’t find NZ Kits on google or Metal Guru… I think if I get another machine it would be a shape oko or a Tormach or if I win lotto a Hass - unlikely since I don’t ever play.

Hi Leith,how they are

And metalguru is on the US open builds cheers Barry

Thanks Bary! I checked it out, you might be interested in linearmotion.co.nz too. They have a fair bit of stock of linear rail, rod, bearings, track etc on hand in Auckland.

Hi Leith, your lucky as Kristans in Auckland,so no postage ,the next one build your own,mine is a C-Beam its nice an big,i took photo yesterday to put here, but it came out crap, wrong lighting.im hopeless at the computer so waiting for son to come over an sort it,i have all my stuff in a small room which I keep heated in winter, rust never sleeps Cheers Barry

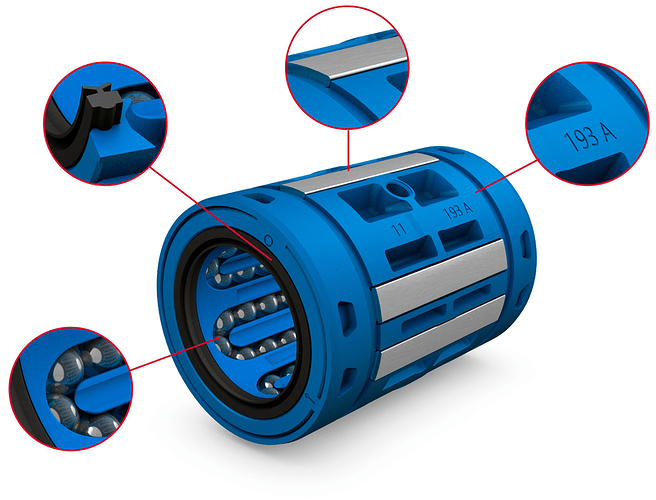

Yeah, I actually have a smoothstepper, G540, 3 x nema 34 steppers, and a bunch of very nice SKF linear bearings that look like this so I should really build something, it’s just I’m working on another project at the moment…

cool you’ve got some good gear then, and theres no hurry

I want to do a mod on my 7x16 turn it into cnc ,so a mate is going to turn the parts up for me,I struggle in the memory department so im finding it hard to learn stuff at 66

loving this, what end mills are you using? Are you doing Muti step passes? I.e a cleaning path?

@Luke There were a few tool changes in the setups—the workflow has evolved a bit, but generally it consists of:

- Adaptive clearing with 3-flute 1/4" flat-end tool, leaving about 1/16" of the stock for the next operations

- 1/8" ball, clearing areas the 1/4" wouldn’t fit (still leaving stock)

- 1/8" ball, parallel pass with a .4mm stepover, with no stock to leave

- 1/8" ball, parallel pass rotated 90°, to make sure all the little nooks and crannies are cleared properly and to ‘de-fuzz’ the piece a bit.

If it’s a smaller piece I’ll sometimes use a 1/16" tool to do waterline/contour cleanup in small pockets and areas the 1/8" tool won’t reach.

Thanks, this is very interesting. Impressive it’s all done with a 1/8. I have never tired a 1/16 but this is impressive.

To be clear, on some of these I used a 1/16" for the final parallel pass to get the nooks and crannies—but you want to use the largest tool you can for the parallel passes because it reduces the size of the cusps as the tool is more flat across the bottom with a larger radius.