Hey there. Have been having a blast with my nomad but since this is my first cnc machine I am clueless as to what kind of maintenance I should be giving it. Any good resources on cleaning/upkeep would be greatly appreciated. Thanks

1- Keep it clean with just enough compressed air to clear chips off the rails and Lead screws.

Ive run Nomad’s with chips all over everything and it doesnt affect the cut, but I do like to have a good visual of the machine, and pictures look better with a clean machine.

2- Listen for any changes,

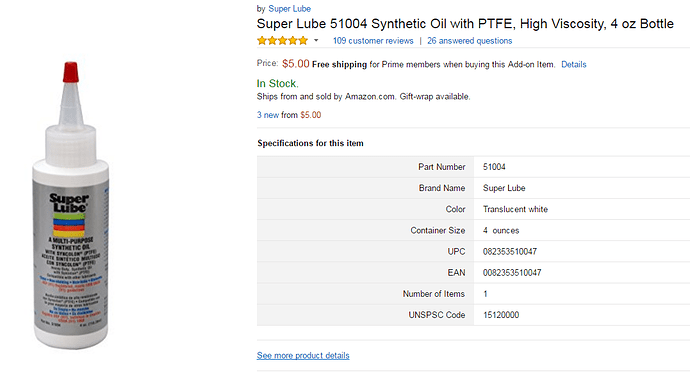

Heres the lube we use in assembly on the bearings and lead screws:

I see Apollo has already jumped on this one, but here are a few more words.

The rails take a very light wipe of oil from time to time. The majority of “maintenance” is really just keeping things clean. Wood chips/sawdust can suck the oil out of bearings, so you want to be sure you clean them off the sliders and bearings.

I make an effort to vacuum everything, then wipe the inside down, take an old paintbrush to the lead-screws and fish things out of the tightest corners with that.

Be careful with compressed air, it can get things airborne that you don’t want in your eyes, and somehow blast chips into places on the box that you thought were sealed. Sometimes there’s no good alternative though.

More discussion here: