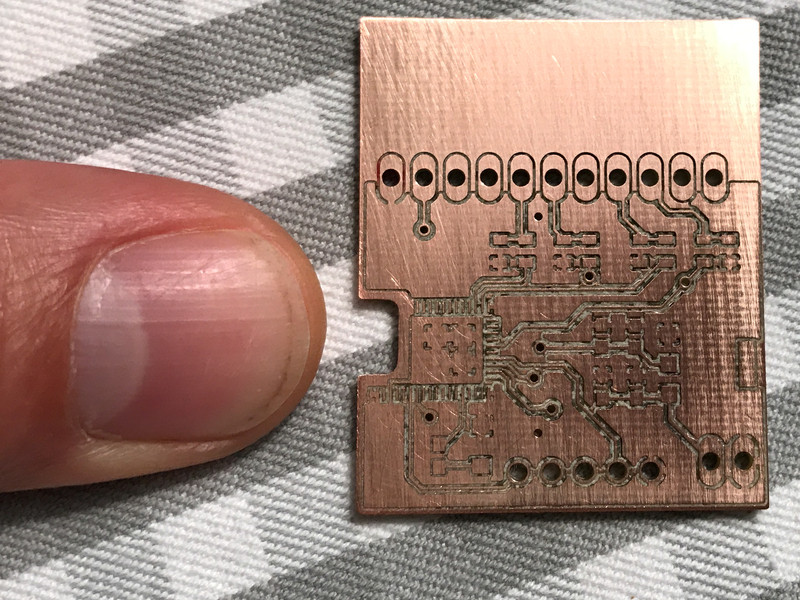

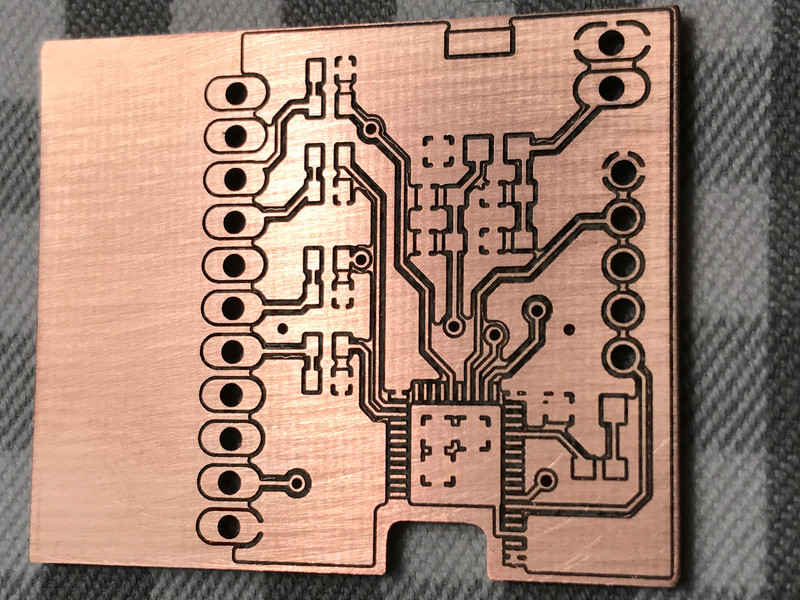

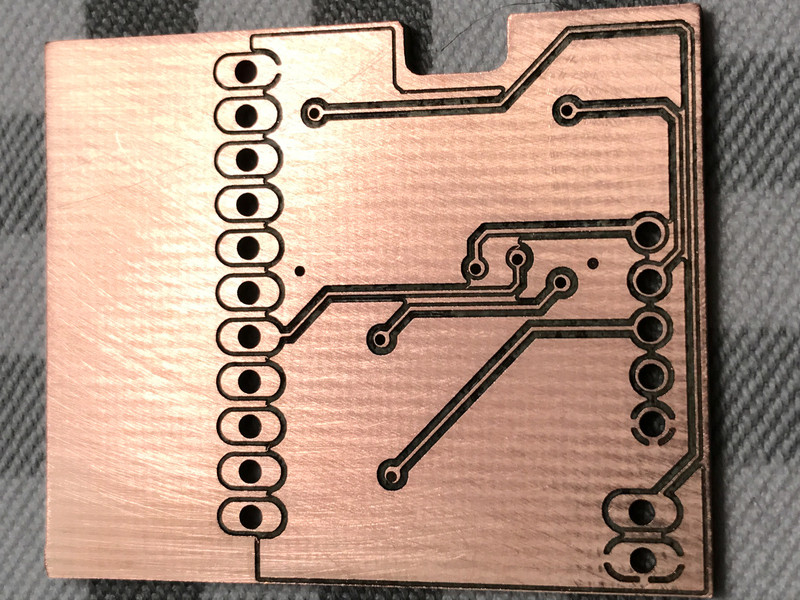

Well after a few broken bits and some trial and error here is my PCB effort. The main component is a 45-pin LGA 0.5mm pitch module. The size of this thing is tiny tiny. I have been trying to figure out what I could put along side it to give some perspective. As can be seen on the bottom side the alignment is not 100% but pretty close. We are probably talking about 0.1mm. Not sure how I could get it any closer! The way I see it the hardest part for a double sided PCB (at least of this size) is alignement and surface flatness.

Now I still have to test the circuit and see that all works…

Maybe my thumb will give an idea of scale. You can also see the “dirt” in between the traces.