I don’t get why people want to change the bed, unless it’s to get some t-slots and that seems like you’d lose a lot of of Z height. And I would think the original picture in the thread would not only be flexible in using but flex under much pressure. But what do I know know…

@Randy - The correct callout is “DRAWN BY AN EE, USE AT OWN RISK”

@patofoto - Glad it helps. This was always something we wanted people to do. If we have time, we’ll probably make a batch of something different too.

@garyinco - We find that most people use very little Z depth in practice. Many of those that need more than an inch or so tend to be using it for fixturing of some type so I can see a threaded table being popular ( but obviously it’s not everyone)

-Rob

@patofoto: heh, I still can’t get the table off. I mean, I wasn’t using all my strength - I didn’t want to break anything - but it did seem pretty much locked on there… Did you turn it upside down to be able to tap up through the slots in the machine floor? You really just removed the 6 bolts and were able to get the table off? I even tried taking the M6 screws and putting them in and pulling on those, as well as getting a stiff spatula (the one I’ve been using the pull up sticky-taped pieces) under the table, but neither seemed to do anything…

Hmm. Mine didn’t take much to pull off. I didn’t turn anything upside down.

Depending on the day and serial number, there are a number of pin types and Loctite combinations that have been used on the table. (And this is one of the biggest points of contention between different people in the shop) Later machines should be using undersized pins and less Loctite to make table removal easier.

You may have to turn the machine on it’s side and use a small punch to tap the dowel pins out from the bottom.

-Rob

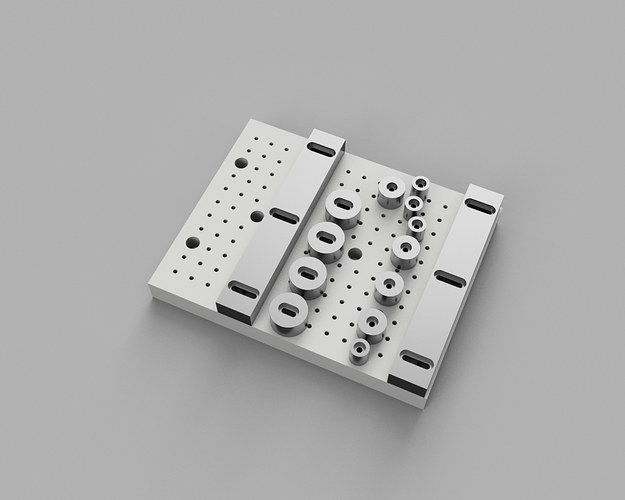

This is table I’ve built to clamp things down.I’ve used Delrin but I didn’t like how it turned out .Its self-lubricated characteristic is perhaps what I should avoid the most. Maybe I should try Aluminum.

The hardest part was to tap all the holes manually (actually, used a drill). Thread mills are very expensive ($80~$150) but I may eventually try them out.

PS.: this is a borrowed design from a comercial product that fits Normad bed fixtures. http://www.hightechsystemsllc.com/pt_work_holding_system.html

interesting system … though unless i’m missing something, at 14" wide it won’t fit in the nomad.

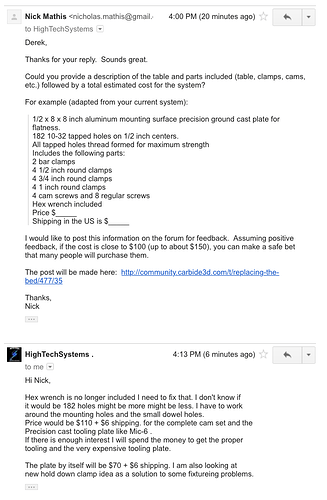

I eMailed Derek Berger at High Tech Systems about making an adaptation of his HTS Modular Work Holding System. He had this to say:

I already make smaller versions for other companies. I would be happy to make these for Nomad in any size. Let me know exactly what sizes you would like. Thanks, Derek Barger www.hightechsystemsllc.com

A modular system like this for about $100 seems worth every penny.

Thoughts?

absolutely! shoot him the pdf and see what he says …

I’s be super interested also!!

I would be very interested in this, too.

I sent him the PDF of the table dimensions and he is checking on how much it would cost to make it. Stay tuned!

If its somewhere around $100, I’m in.

Staying tuned!!. I’m also in!..

I’m also in! Keep us posted.

UPDATE:

As per my conversation with Derek Berger at High Tech Systems …

I will keep you all updated as I find out more.

Thoughts so far?

Sign me up! Including 20 characters so the forum will let me post.

What I wanted to mean was that I made the design to fit Nomad, not that HighTech’s bed would fit the Nomad.

I’m in for a bed like this. Thanks!

I’m in! Sounds like a great way to facilitate holding stock. Would love to hear what our great folks at Carbide 3D think of this. Any comments?.