So tonight I started my waste board. I’m doing T-Nuts on a 2" grid 15 on the X and 15 on the Y. I decided to add a few more rows out side the max area of the XXL in case I wanted to take full advantage of the cutting area. So I went into Fusion I added a 16th row in my model I then applied my tool path to that single row along the Y axis. Went to the machine slide my waste board over 2" and ran a couple more rows of pockets for the base of the T-nuts. On closer inspection not only are the pockets shallower then the 225 of the original cut but the are smaller in diameter aswell. They are exact same size in the model, I used the same bit and same 2D adaptive pathing but the last 2 rows are different and I can’t figure out why. Any thoughts? I must be missing something.!

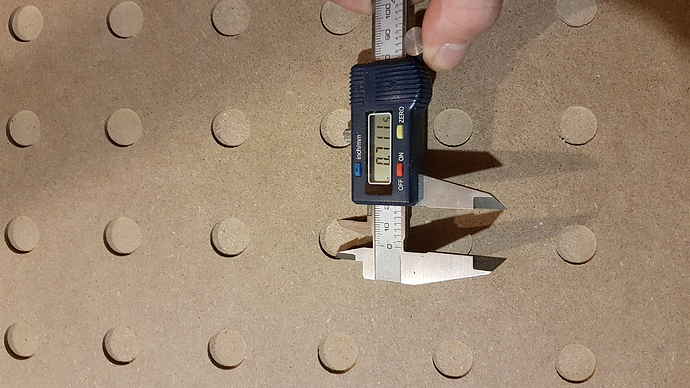

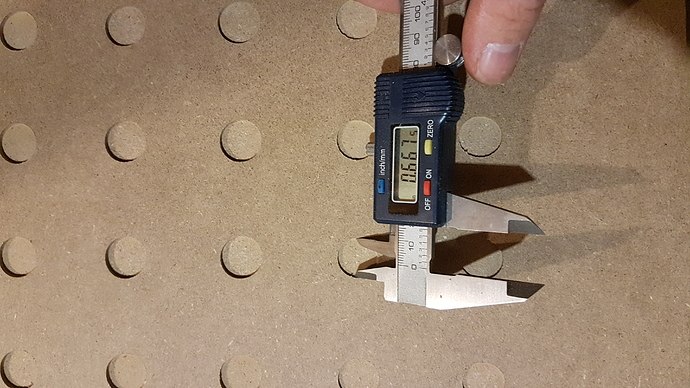

You can see from the photos the difference in depth aswell.

Because your machine position is determined buy timing belts and extruded timing pulleys…and they are made well, they are NOT very precise. This means the machine will be not as accurate in different locations. Read this from a previous post:

AND:

Still a great machine…you just have to work with it.

That’s something like a 6.6% error — that it’s so consistent makes it seem as if it’s some difference in the CAM setup for the affected circles (they are centered on where they ought to be or no?).

I’m having a hard time wrapping my head around how it could be a belt stretch or quality issue and be localized to only the sizing of the holes — wouldn’t the positioning be affected as well?

Often pocket depth is insufficient Z-axis belt tension — check that as well.

I experienced something similar where the last row (towards the back of my shapeoko) had issues because in the process of creating the pockets, the carriage was hitting the Y limits, the wheels would touch fastener for the belts. As a result, the pockets were eccentric over the holes and this issue continued on the following rows because the Y became de-calibrated. I eliminated the last row and the problem disappeared but wasted to wasteboards in the process.

Thanks Guys I got it figured out. After going over everything in my tool path I discovered I had left the “Stock to leave” on at .002in" I’m assuming this must be so you can come back with a finishing pass. Still have lots to learn the options in Fusion can be abit overwhelming.

Thanks for your input.

This was why I didn’t have an answer, but it all makes sense. Share your Fusion files when you get stuck. Some of us have made all those mistakes before.

@RichCournoyer He slid his stock over, so it was in the same location on the machine.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.