The only other concern I would have is the size of the solder pots in the plug. I looked at mine and am not sure you could get all the strands in it. It will be tight. If your has a smaller plug being a smaller 1.5kw spindle 16 AWG may be the better way to go. 16 AWG will carry 10 Amps, and 18AWG will carry 7 Amps. In a multi core cable with 3 conductors. And small cables tend to flex better too. Just some food for thought.

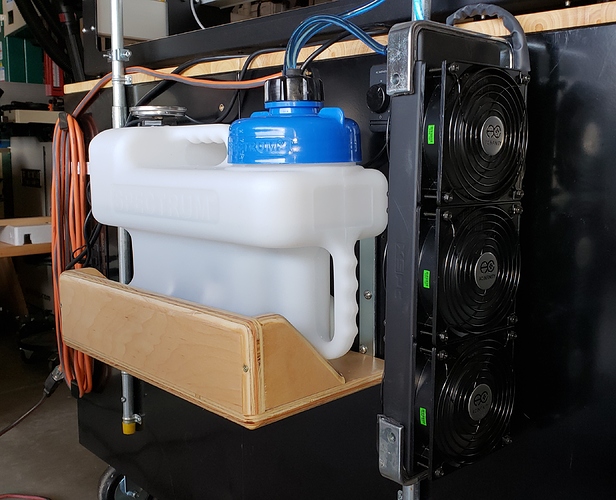

I would also use a cheap Aliexpress or Made-In-China Laser engraving chiller which includes the pump. It will keep your tank at a chilled temperature, which is constantly monitored and aided by multiple fans. I use a CW-3000, which costs about $120 +shipping depending on what part of the world you are

Are you using a laser chiller to cool your spindle. From what I have read some spindles need a little bit of warmth to run properly. I guess the bearing or clearances on the shaft need some. Some units require preheating without water or load to get parts to temp. Mine says nothing about it though. Once I get mine up and running I will have an idea of temps. I did buy a DC pump on Amazon that has 20 stepped output for fine adjustment. But thanks for the food for thought.

I would think a lazer chillier is massive overkill. I have a 20l tub and £15 pond pump…

I also don’t like the idea of condensation forming on the spindle.

I would always go for shielded cable. Troubleshooting interference is a pain in the butt just best to limit all possibilities and have a reliable machine. Don’t want it to disconnect 90% into a 6 hour carve.

I made a post regarding cable questions that may help you:

The robotics cable mentioned there is something very similar to what I went for.

I found my supplier locally. I went to a commercial electrical supplier and got VFD shielded cable.

As for cooling, they make these spindles in aircooled variants and they run just fine.

I used to do custom PC water cooling setups as part of my previous employments, often people would go absolute overkill. It was fun to make but a real waste of money.

Water cooling is orders of magnitude better than air cooling, I believe that a modest setup will be more than sufficient. Condensation is a real problem with any sub ambient (more specifically sub dew point) cooling.

I did some decent hogging out of 25mm thick aluminium block to make some brackets and ran if for about 3-4 hours. The water was only just perceptibly warm, all this and I dont even have the fans running on my radiator.

Here are some links you may find useful for setting up the VFD and if you want to add a trimpot for RPM adjustment.

VFD Settings:

http://www.halfbakedmaker.org/blog/post_id

Adding a trimpot:

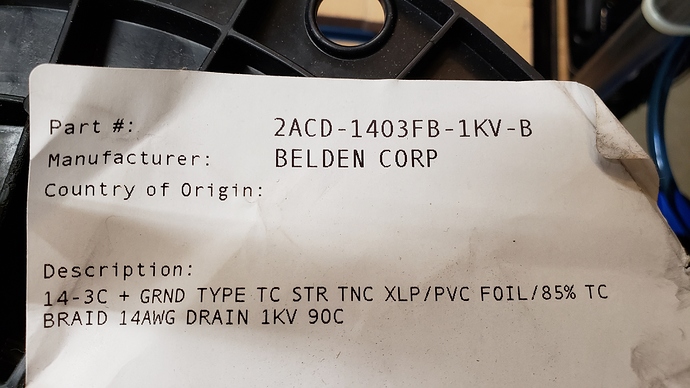

Ok. I need some advice. I have everything installed just need to terminate everything. I have 18 x 40 mm drag chain and Belden 14/3 shielded cable. I’m looking at it and just don’t think the drag chain can handle the cable. I need some opinions from those who have gone before me. Is this cable over kill if it is recommendations for a better choice, and if not should I hang it down from the dust collector boom with the dust collector hose and cooling lines?

Looking at the product label on the spool it appears to be 14-3 cable, but they could have used a different spool to ship the correct cable. Is the jacket marked the same? You could zip tie it to the side of your cable chain. Not sure what the bend radius is and how flexible it is.

Yes Lew your right. Typo on my part. It fits inside the chain but because of all the shielding and associated insulation it’s 16 mm across. I can move it by hand just really thick.

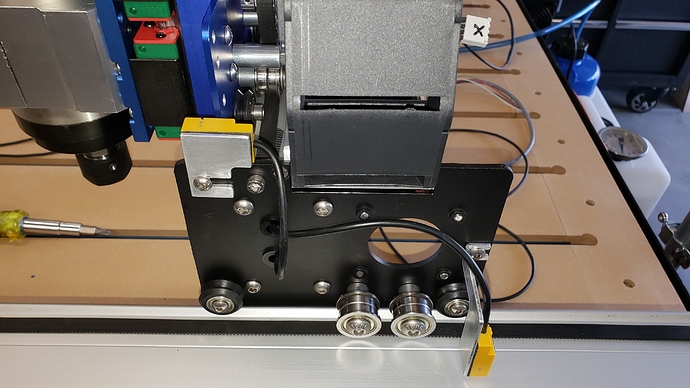

Hey Luke. I’ve never said this to a guy before and will most probably never say it again. You’ve got great nuts. The eccentric nuts you sent me are a .major upgrade over the Shapeoko factory nuts. Also I replaced all the V wheels with the upgraded wheels you sent me so I’m going to need to order spare wheels. I do have the issue of no screwhole for the X axis limit switch. I drilled to fit the center of the HDZ with a small amount of adjustment room. When I put the Suck-it wings on there is not enough play to center up on the wing. I know there is an upgrade for the wings. But would like to know how the new ones differ from the origional before I drill and tap another hole.

Thanks

I found this pump that says its 24VDC but it also says 3 phase 20 step speed control. With my setup it gives me a measured LPH rate of 41 to 58 liters an hour. I think that should do. I have an 11 liter recirc tank and the pump is submersible.

I love the flow indicator - totes buying one.

You don’t need the fans on the coolant tank…

Your cable looks way thicker than mine… Does it bend easily?

Not as easily as I would like. That’s what concerns me. Is your cable shielded? I know in many installs it is important to have good shielding I’m just not sure in this application if it’s that important. As for the radiator it can reach as high as 43°C here in the middle of summer so I thought it would be a good idea. Although if it’s that hot I’m probably not going to be in the garage.

Nah mine isn’t. I would worry about it’s lack of flex mind.

Yeah, the flow indicator is cheap insurance and not much to go wrong with it for a couple of quid it’s worth it.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.