Hey Scott, I had the exact same issue, and believe I have fixed the issue(SOLVED). Here is my post from here - re-posted below. Hope this helps.

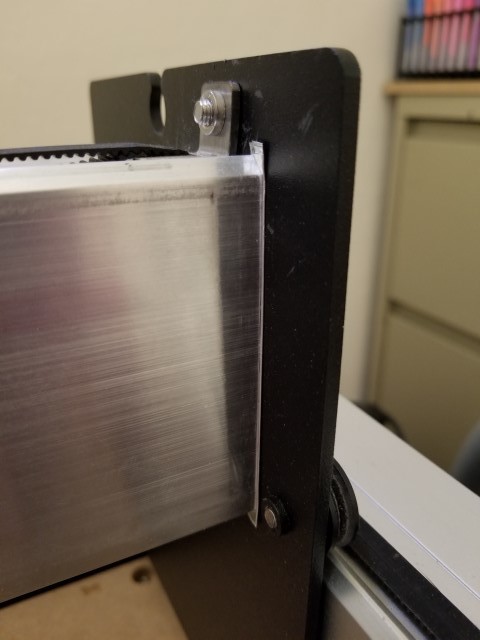

Same Problem (kinda solved) (so far). Gantry had a 1/16" gap on one side. Fortunately the gap was on the left on the front (when gantry full forward), and on the right in the back (gantry full aft). So skewed like a parallelogram… Tried everything, until now… I think I got it.

Now… (Here is my approach)(worked so far)

Took most of the Shapeoko 3 apart.

Loosened “ALL BOLTS” (That’s the wasteboard, Y Rail, X Rail, all…)

-Found a large piece of glass for the Shapeoko 3 to rest on (level surface).

-Replaced all bolts with longer bolts, washers, spring washers, and nuts to allow easy tightening (I tighten nut, not bolt. Like a stud) (this is not necessary. But I do recommend the spring washers).

-Big step here… LOOSEN THE V PULLEYS! (8 V-pulleys allow the gantry to slide fwd and aft) (loosen them all) .

Slide the Gantry all the way forward.

-Look for a gap

-If there is a gap … Big step here… Pick up the front of the Shapeoko 3 by the frame  twist the frame base left or right to fix the gap (imagine you are straightening a parallelogram). Check the gap. Continue to adjust the main frame left or right from the front lowest points.

twist the frame base left or right to fix the gap (imagine you are straightening a parallelogram). Check the gap. Continue to adjust the main frame left or right from the front lowest points.

-Once gaps are resolved, tighten the front main rails only ( the 8 bolts facing you). While holding the gantry forward touching the forward frame - Tighten one bolt on the left, then the opposite one on the right. Then left, then right… Till all 8 are snug.

-Tighten X-Rail bolts (left and right) (8 bolts) one on the left, then opposite one on the right, back and forth, while keeping the gantry tight against the forward frame.

-Tighten the aft main rail bolts (8 bolts). left, right, one at a time swapping sides…

-NOW tighten the V-pulleys…

Just to clarify - Tighten in this order (1 fwd Mains, then 2 Gantry, then 3 rear Mains):

3-------3 aft main rails 4 bolts a side (8 total).

I I

I I

2-------2 gantry, 4 each side (8 total).

1-------1 fwd main rails 4 bolts a side (8 total).

Slide gantry aft. Check for gap. I did not have a gap, so I don’t have any suggestions if you do.

Now, I am going to reassemble the Shapeoko 3. Once assembled, I will repeat these steps.

NOTE: If you cannot fix the gap with the above steps, try rotating the X-rail upside down (they are mirrored). look for the gap. If that doesn’t work, try flipping the main rails upside down, maybe swap sides… Look for gap.

I will post when complete with final results…

twist the frame base left or right to fix the gap (imagine you are straightening a parallelogram). Check the gap. Continue to adjust the main frame left or right from the front lowest points.

twist the frame base left or right to fix the gap (imagine you are straightening a parallelogram). Check the gap. Continue to adjust the main frame left or right from the front lowest points.