@ChiknNutz

The Frame is threaded and the scales are designed to have through holes.

@ChiknNutz

You may want to check out Jantz knife making supply.

Heres the fasteners page link:

http://www.knifemaking.com/category-s/75.htm

I mean to hold the scales while CNC routing them. The reason is because the screws are so small, like a #2 or #3, there are no inserts or helicoils that I can find this small to put in a piece of wood. Next choice would be aluminum, but for the long term, not sure this is a good option either if used more than a few times (threads stripping or galling in the aluminum over time). Don’t really want to use a steel plate, but that may be the best option. Have been looking into vacuum fixturing, but there really isn’t enough material to properly hold them (1.5" x 3.5"). Further, I am not even sure the screws will hold due to side load of the cutter unless the feeds are really reduced.

@ChiknNutz

You can use double sided tape or clamps.

Hot glue may work as well depending on your material.

I recommend leaving a thin skin on the material.

If your part is breaking free, you can reduce the DOC.

Have you seen this video:

The material is kinda spendy, so near-net size is used for the blank which precludes the use of a clamp. Dbl-sided tape may be okay for a few, but this is more of a production run of parts (dozens, 100’s perhaps even 1000’s is possible). Am considering trying to leave a skin as I’ve seen mentioned elsewhere for similar purposes, but still need a means to hold the near-net blank.

Sorry, didn’t mean to hijack this thread, should probably start a new one so this isn’t all co-mingled.

Probably deserves its own thread, and I can imagine some custom setup will be the result.

What is the material?

Three materials will be used…Dymondwood, bone and ivory.

Whatever happen to this? No interest? Sounds cool to throw a project out every month or so. Did you end up with a finished knife appollo? Ray

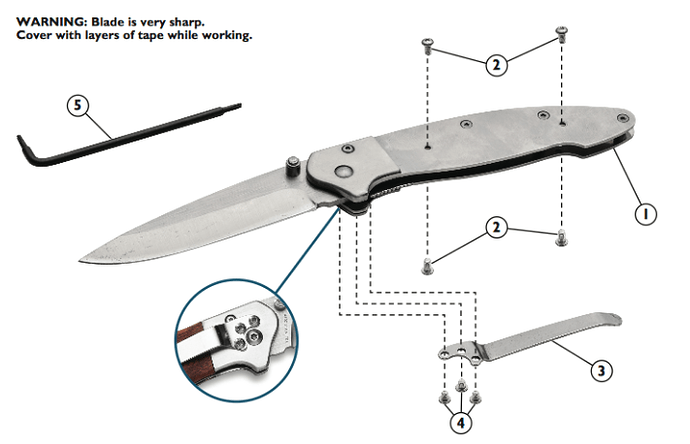

This was the First Weekend Project and I used it to demonstrate a useful function in Carbide Create.

To bridge the gap between existing products and custom CNC parts I showed how to scale and trace in Carbide Create.

You can place an image or photo as a background image in Carbide Create, then Scale it, then you can trace it and cut it.

I refined the file and cut a couple tests parts in clear blue acrylic.

I posted the DXF and Carbide Create (.c2d) file above if you want to try it.

The second weekend project is here:

Do you have a material, theme or specific project on your mind?

Request lines are open.