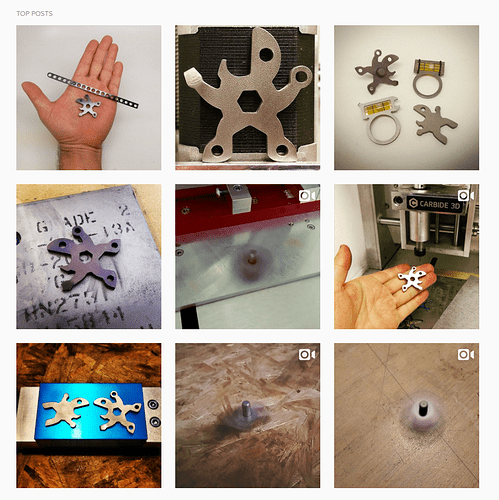

For this weekends Project I wanted to share the file for the #TiFightingFrog in Carbide Create.

It is a Pocket Tool / EDC design project, inspired by the creative designs Ive seen on Instagram.

What makes this one unique is its compact size and balanced geometry allows it to Spin like a Top.

https://www.instagram.com/p/-E2ayFLSrJ/?tagged=tifightingfrog

Feel free to try the file, modify it, hopefully it inspires you.

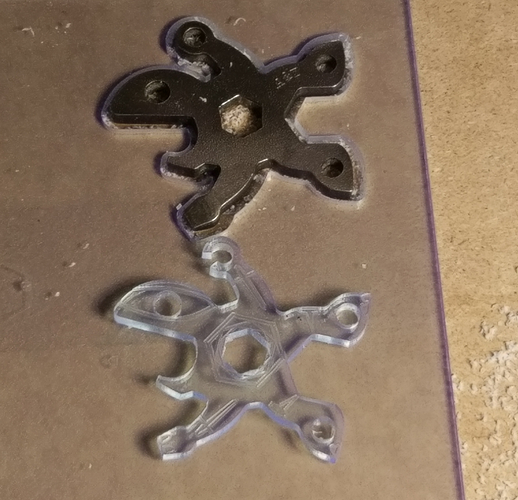

I will continue to modify the file and cut it out of different materials, the file attached below is setup for Titanium on the Nomad with a 1/16th endmill.

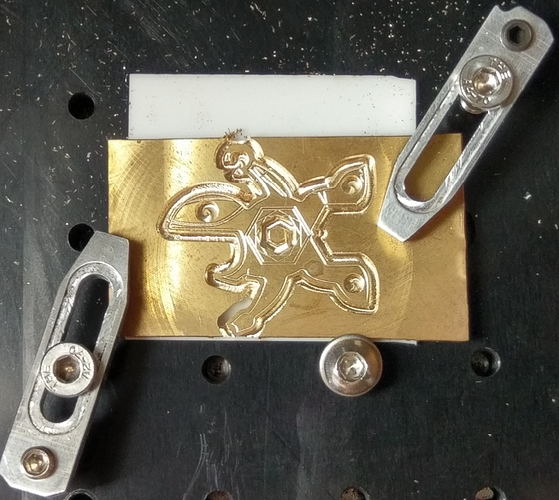

This weekend I will be making a Brass Monkey version and may attempt to engrave it for next weekends project.

If you do make one, post a picture Y’all!

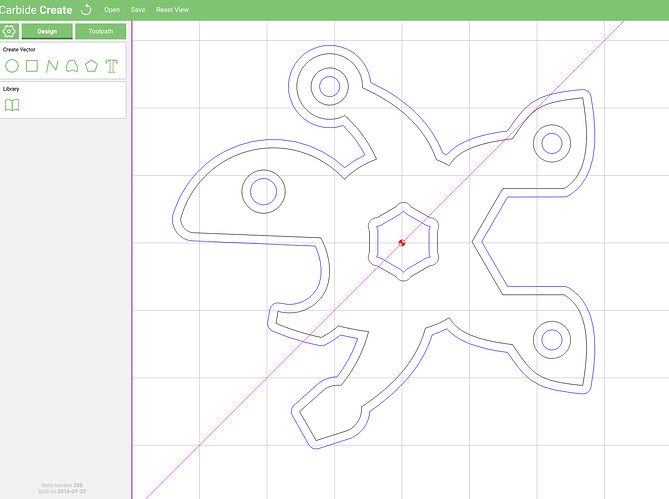

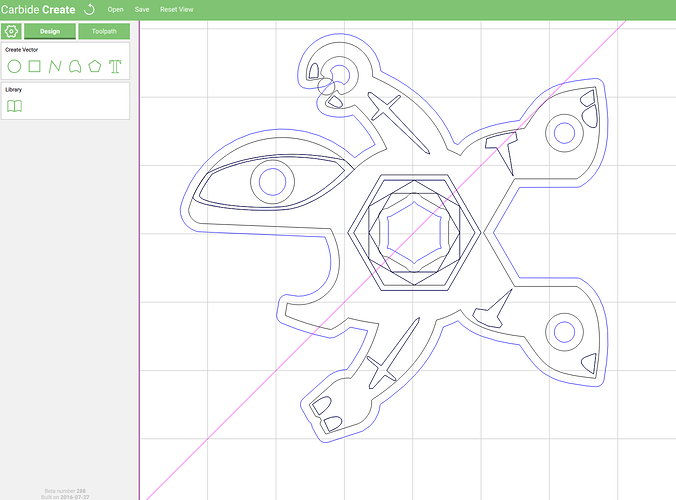

I imported the Ti Fighting Frog DXF file into Carbide Create, and it needed to be scaled which is why you will notice the file has a 2"x2" square.

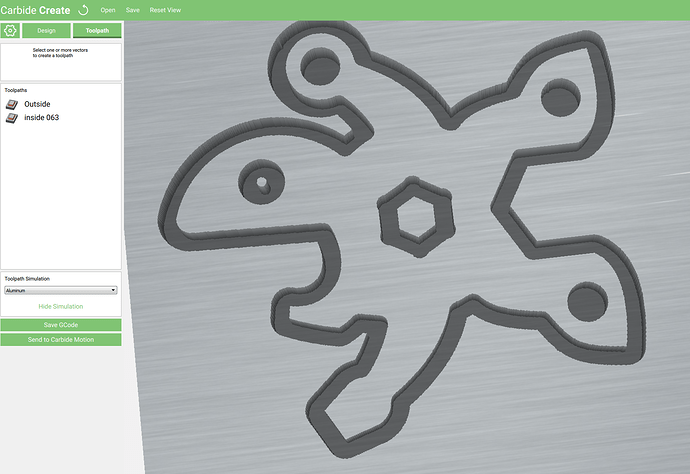

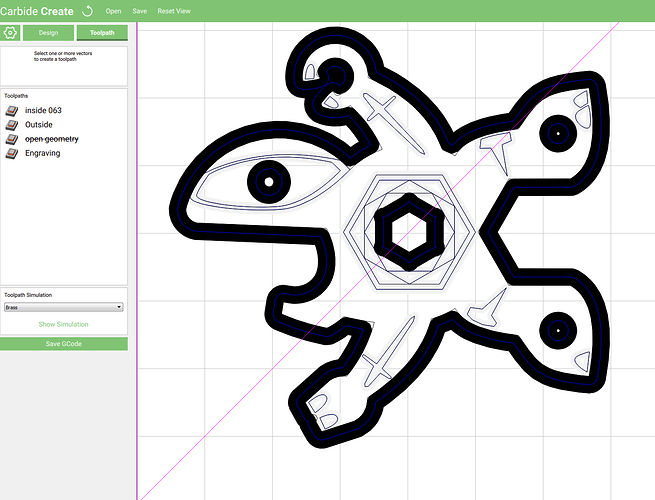

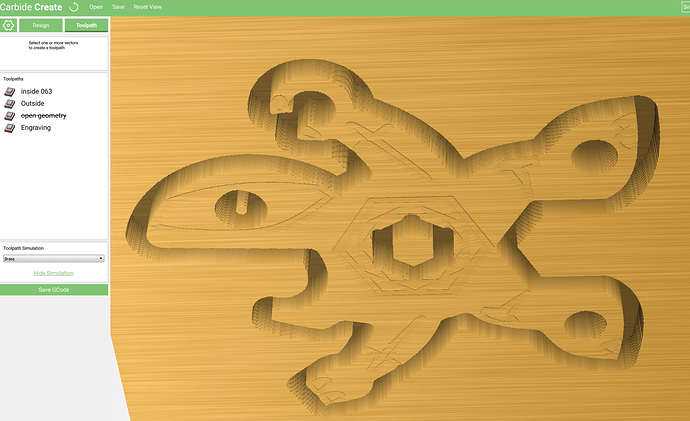

Carbide Create Toolpath Preview- this file is setup for .125" thick material.

With the Feeds and Speeds charts you could cut this out of lots of materials, but if you want long spin times, use the heaviest metal possible.

You will need:

2" x 2" .125" material

1/16th cutter

Blue fixturing wax

For Titanium or Steel cutting you will also need:

Hot glue gun

Coolant.

TI FIGHTING FROG 063.c2d (564.4 KB)

Heres a link to the original Post with the very first prototype made on the Original Nomad 883: