it often hangs during the X homing about 5in from where the switch is triggered. Power-cycling fixes that.

Reason: The homing cycle times out - if your machine is say in the extreme front left corner, it may not make it back to the home position before the timing cycle runs out.

Solution 1: Click MDI, type $H then click send, this will restart the homing cycle. If you are in CM4, just click ‘initialize machine’ again.

Regarding the interference: there isn’t a silver bullet to the interference, it could be several different factors. I’ll list them off here, and we can use this as a troubleshooting list.

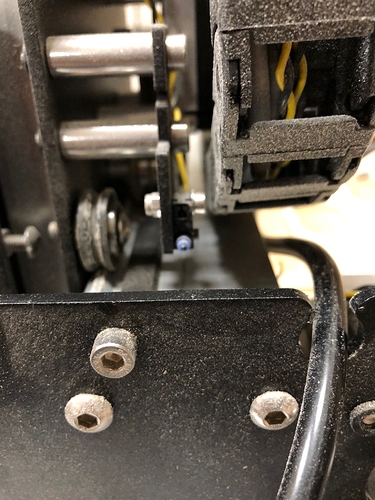

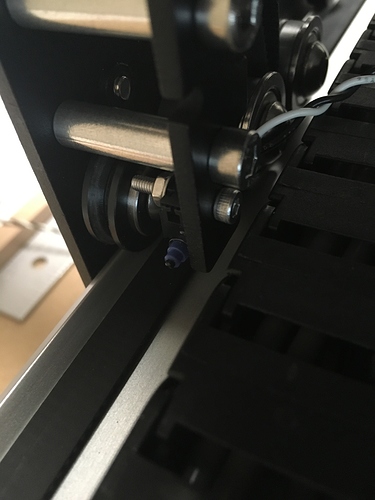

1.) The switch is on the wrong side of the plate. This should be less of an issue now that we pre-mount the switches to the plates during the pre-assembly of the wiring harness. Here is a picture for reference of a correctly mounted plate.

Solution: Move the switch to the other side of the plate. Make sure the screw head is on the opposite of the plate as the switch.

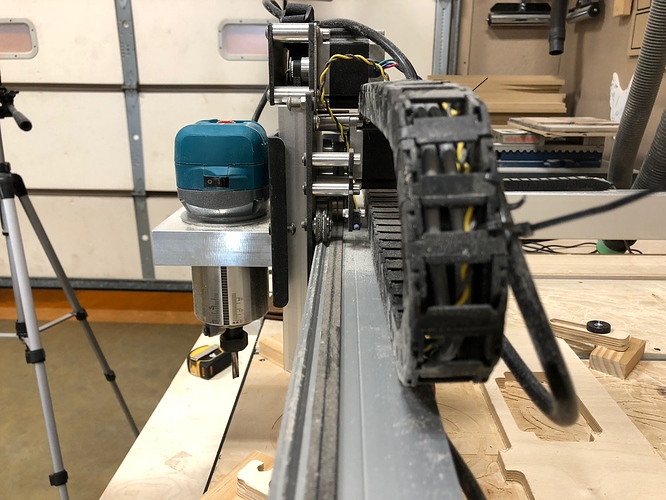

2.) The drag chain is too tight. That is, the spot where the drag chain end is taped to the extrusion is too close to the Y-left plate. For reference, the drag chain should be about 2.5" away from the left Y plate.

Solution: Adjust the end of the drag chain to be further away from the Y-Axis left plate.

3.) The drag chain is at an angle towards the front of the machine. This will cause the screw head of the limit switch to interfere with the drag chain as it gets close to the Y-Right plate.

Solution: Adjust the drag chain so it is running perpendicular to the X-axis rail. You can even cheat this so it’s running away from the rail towards the back slightly.

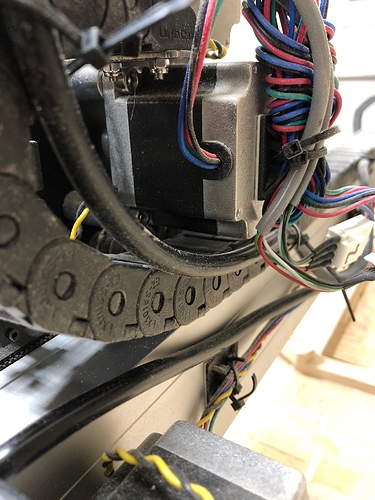

4.) The power cable for the trim router is binding between the X stepper motor and the inside of the drag chain. Here’s a photo showing such a scenario.

Solution: Secure the router power cord to a better location on the drag chain. With the power to the machine off, slowly slide the X/Z left to right to ensure the interference has been removed.

Hope that helps, if anyone wants to see more specific angles, let me know.

_Edit: More ‘official’ docs article can be found here: http://docs.carbide3d.com/software-faq/x-limit-switch-failure/_

-Edward

That one’s on me.

That one’s on me.