<img src="/uploads/default/original/2X/f/fead0e36275df082e084d5134f60bce298d2ba0f.jpg" width=“640” height="427"

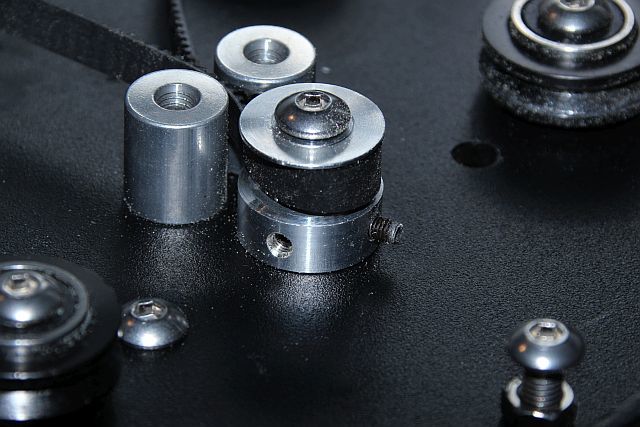

I have had my Shapeoko XL for about two months and all has been well. I was running a job this afternoon when it became apparent the Z Axis Plate became frozen in place. When I disassembled the mechanism I discovered one of the two set screws on the idler pulley had vibrated loose (see picture) and jammed the gear from turning, making a loud clicking sound (not a belt skipping sound). It appears that the set screw had little or no LocTite on the thread.

- Can someone please explain the function of those set screws. If you tighten them down, they lock the pulley against the mounting bolt also preventing it from turning.

- Now even more curious, the belt will not bypass itself because the bushings appear to be pinching the belt too tightly together. I don’t have a clue why this is since it is threaded exactly as the instructions indicate and it was working well before this incident…

- Also, the loose set screw scored the vertical track on the left side. I was able to smooth it out somewhat with steel wool, but hopefully the factory can send me a replacement.

Your thoughts and suggestions on issues 1 & 2 would be greatly appreciated.

Thank you!

Don Sieburg

and prevents the pulley from turning. The two bushings adjacent to the pulley are too close together.

and prevents the pulley from turning. The two bushings adjacent to the pulley are too close together.