Hey, does anyone have settings for a 3/4 Straight bit that they wouldn’t mind sharing? I don’t know where to begin as far as adding new tools into the library for some bits. Because even though the whole of the bit is 3/4 I don’t know the thickness of the itty bitty blades on either side and I know that’s what matters when it comes to the docs and what not. If someone could share a good starting point or some settings that are working real good for them in Wood/MDF I would appreciate it?

Not knowing the bit or brand you have most bits come with a drawing of the bit with the measurements. You don’t kneed to worry about the individual flutes and the thickness of each one but you need to know the cutting diameter, cutting and the length of the bit.

Anthony

Ok, so Diameter is the 3/4 I mentioned

length is 1", but a straight bit only reveals so much of that one inch on the bottom side of the bit, so I thought that would be a factor, It’s hard to tell how much of the blades reveal, I couldnt really get my calipers on it, but it was close to like .05 Oh, and the brand is just some craftsman straight bits I got from lowes years ago

What are you going to be doing with this bit?

This bit is for making rabbiting cuts on a router and it is designed to start off the material and begin the cut on the side not plunged down. It will burn your material if you are making plunge cuts with this bit. If you look at the carbide it is nearly level with the body of the bit and any plunge you make will cause the bit to bottom out on the material can your plunge may lose steps, may drag and cause burning.

Anthony

You make a valid point, I have to make the doc very slight to use this in the manner I wanted to. I wanted to use it to hog out a bunch of material before then coming back with my narrower bits. I’ve done it before. took for ever, hence me asking the community if maybe they had some nicer settings than what I’ve got. May just be a matter of it “having” to take a long time, since i don’t have much doc to start with

I generally don’t make recommendations for tools or components that will be used in methods they are not designed for. I always suggest get the proper tool for the job. You should be able to find a 1/2 cutting diameter bit that will make a plunge cut and make it work better than what you are doing now.

With that said if it worked for you previously use the same settings you did before.

Anthony

Yea, hopefully someone who’s tried it with better results will chime in, but thanks for your input.

I’m chiming in because I didn’t read about what machine/router you are using that 3/4" bit on.

lol. oh. Apologies.

Shapoko 3 XXL

I have a 3XXL. I use a 1" bit, but just for surfacing, and I don’t take much of a bite with it.

The main thing about the larger bits (as was mentioned by @avetrano), is that you really need a ramping strategy on entry. They don’t have cutting surfaces in the center. If you push it, you’ll start losing steps somewhere.

RPM should be watched with feed rate, because burning is easy.

Aah I see. And since i use Carbide Create, I don’t have a ramping feature do I? Is that like available in one of those Vetric softwares? or does CC have one that I’m just not aware of?

Carbide Create has Ramping in the Pro license:

732

- (NEW PRO) Ramping for pockets.

731

- (NEW PRO) Contour toolpaths allow ramping.

Aaah. The pro. Gotcha, thanks

compare it to the McFly, but I think the 18000 RPM for a 1" tool is too fast.

I would go about 10000 RPM, up to 120 IPM, start with 0.020 DOC & up to 0.375 stepover.

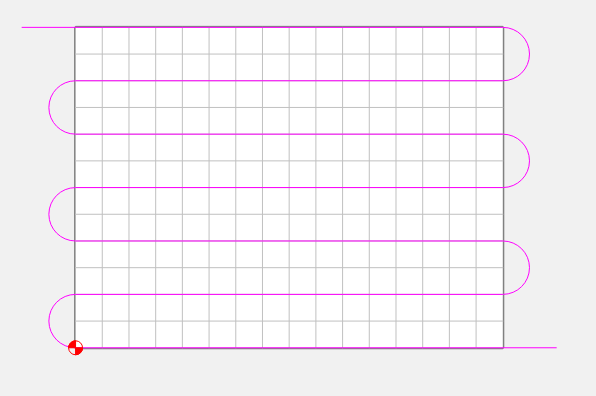

If you’re going to pocket, use PRO & ramp no more than 5°, I would even go 3°. Otherwise, make sure you are starting off the part. This is a cleanup / surfacing path I use

Thank you for this. I appreciate it.

This topic was automatically closed after 30 days. New replies are no longer allowed.