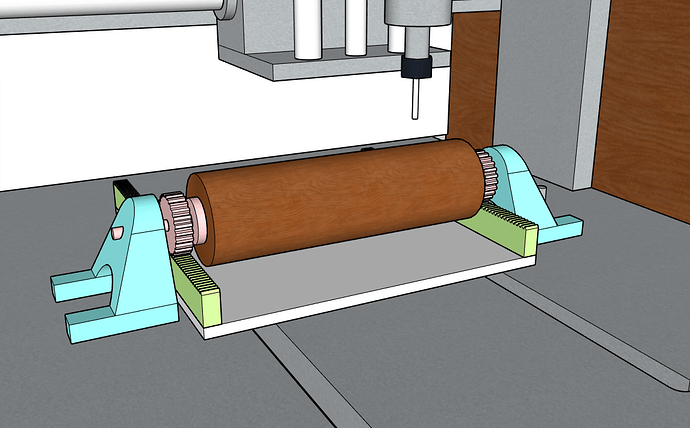

I recently made a 3D model of the Nomad (3D Model of the Nomad 883 Pro), mostly so that I could follow it up with this idea of a rotary axis based on the Y plane, as Will describes.

I could probably machine all of the parts required on the Nomad, but would be grateful for any practical advice. My first concern is being able to clamp firmly while allowing free rotation. Has anyone attempted this already?