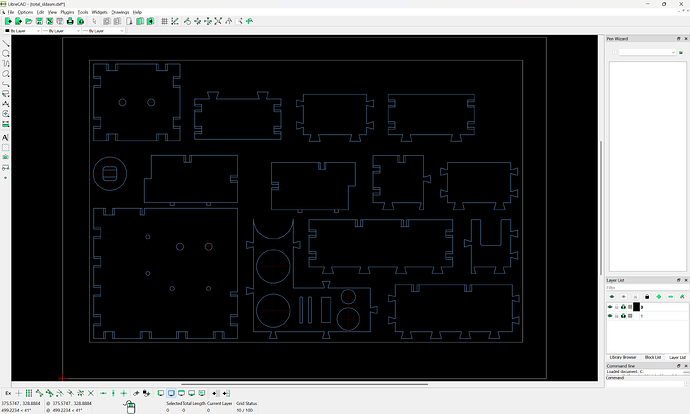

Just to give you an idea of what you are in for, here is a screengrab showing how things are laid out in the DXF:

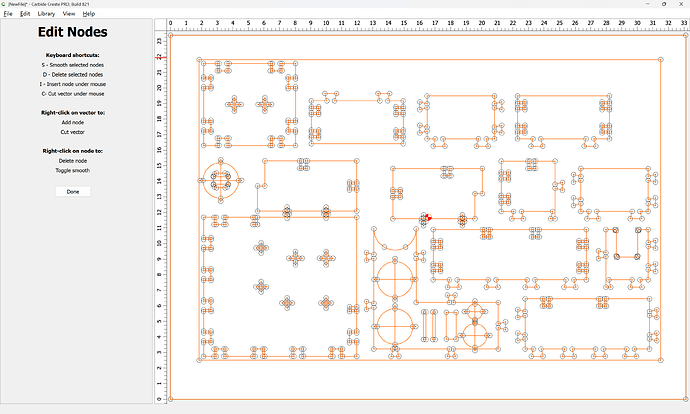

Note that the joinery is drawn in, and expected to be cut in 3 dimensions, which will be rather difficult to achieve in Carbide Create, also, importing the DXF directly will result in polylines, rather than curves. Exporting as an SVG from LibreCAD and then importing into Carbide Create will yield a better result:

This is a rather complex project — I would suggest practicing joinery a bit, the canonical example is:

which I discuss a bit at:

That said, I’ve been experimenting with full-blind box joints which are pretty easy to lay out, and which cut well on the machine, most notably, cutting flat on the bed (as opposed to requiring vertical workholding):

and for a more complex example:

Note that this sort of joinery requires a narrow 90 degree V endmill. Once you’ve drawn up and cut a couple of boxes, improving on this design, and then re-working it to use this style of joinery should be pretty straight-forward. I’ve been working on a programming tool to automate this, but I’m taking a bit of a break since the final step which the tool needs is a rather intricate optimization change.