I’m sorry yall, I’ve gone a couple days without asking this, but I’m just not finding the information I’m needing after searching and searching. I just cant figure out how what should be entered when adding new bits to the library. I’ve been wanting to add a new 20 degree v bit I got, a Corebox bit, I mean, how is one suppose to know plunge rates, feed rates, depths? Again, sorry if this has been asked

I usually go by what a similar bit has and maybe drop 10-30% depending on how fragile I think the bit is in comparison.

Winston had some good suggestions on this on a recent live stream as well. Let me pull that up.

Edit: found it:

Hadnt really even been able to find info on a “similar” bit. Found something on the 1/4 end mill and the 60 v bit, mighta seen something on the 90, but nothing on core box or 20 and with the 60 being so far off from the 20, I didn’t know how much I should pull off of the 60 settings lol. Crazy new world for me lol

The core box isn’t a supported geometry EDIT: in Carbide Create — you can enter it as a square endmill, or a ball-nosed and give up the accurate preview.

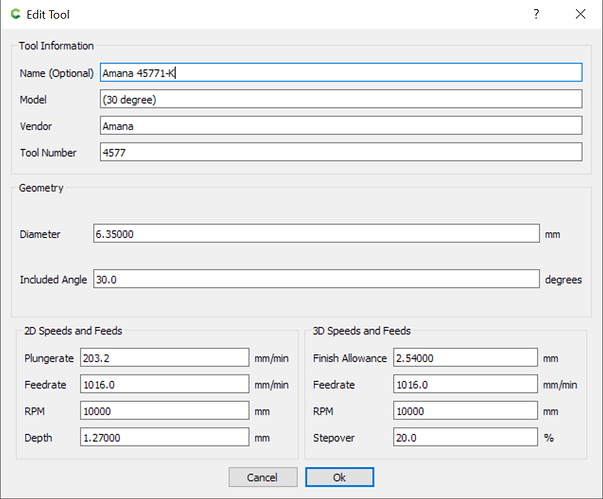

For the 20 degree endmill, here’s what I’m using for a 30 degree endmill in hardwood/plywood:

Lets back up a step to ask: what software?

It matters because different packages handle operations in different ways.

If you could provide more information about the bit and the material, that will also help (manufacturer, bit model, number of flutes, end form- sharp point or flat of what size- material you are cutting, and so on.

The thing is, there is no one answer. If you are using a v-carving software package, the data will be different from if you are using a CAD package. Each package will have differences in the strategy (some allow multiple passes to limit tool load, some will allow you to rough with a different tool so as to protect the finish tool from the heavy material removal, some just plow a path like a team with a six disk gang)

All of this goes into the tool setting.

The tool manufacturer should provide parameters and give the conditions under which they apply. Ask. If the manufacturer won’t give you information, I would stay away in the future if possible. If they won’t help, check other manufacturers for similar tools and steal the numbers, and maybe back off twenty percent on plunge and feed rate to see how the tool reacts. Not too much. Too slow cooks cutting edges due to rubbing. (One reason I pay more for tools than many people here is that I get support from the manufacturers and tools that match the specifications. The 60deg vee bits I used for the recent vee carve thread tests were generic from an ebay seller that comes up here a lot. The tool form was not as specified, as it turned out.)

for reference:

Repuatble manufacturers/suppliers that have been helpful to me in the past include: Helical, Micro100, Harvey, Kyocera, Maritool, Carbide depot, Lakeshore, and several others. These come quickly to mind.

EDIT: part of my confusion is hat a corebox bit is a short round end, not a vee

Fair question. I’m new, so I’m using everything Carbide3d: Shapeoko 3 XXL, Carbide Create, Carbide Motion. Thanks for the advice. Lastly, it’s not that I’m thinking a Core Box bit is a V Bit, it’s that I’m simply trying to expand my library due to the ideas I have and the different carves that will come with those ideas.

Thank you for sharing this Will, I really appreciate it. It’ something atleast to start by

In the past I have emailed Whiteside Bits and gave them the model number and asked for their recommended F&S. Some bits I have I do not know who makes them or they are made in China and they do not provide customer support. As suggested above you can just see what a similar bit that Carbide3d makes and start from there and then it is trail and error. I have learned to stick with name brand bits and you can get customer support. The unnamed bits and bits that are not traditional CNC bits are strictly trail and error.

Gotcha. Yea, I have noticed that the bigger names seem to put more info out there, though some of the generic bit that I have, do provide their dimensions, just not anything I’m suppose to input as far as Plunge Rates or Feed Rates, etc.But hey thanks anyway man, I’ll just wing it and do my best

go back to that spiral notebook we talked about.

my book… front starts with projects and notes on those projects

the back cover, notes on abbreviations and programs / quick reference

few pages starting at the back… notes on how bits react to speeds and feeds and materials.

now to your part…from the back pages, you will start to form ideas and processes on what bit and how to use, that bit.

those notes and back pages will help quite a bit when you get new bits and wonder how to configure the settings.

seems (for me) it is easier to write those things down and compile until I can get a clearer picture of what I am wanting to do -vs- bit choice (how the bit acts). Then I build it into the tool folder.

Probably not the most efficient method, but it works for me and is easier than cluttering the computer desktop with open notepads.

Have not snapped, bent or burnt up a bit yet.

since I said that, I may as well go downstairs and snap a few bits.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.