Need help!!! advanced vcarve… I have tool paths set in advanced vcarve, enabled pockets. It ran the pocket and then went stationary, did not tell me to change tools. My only options were start and stop, unfortunately in stopped it to do the tool change but now I would have to start whole project over again. It is a 3 + hour project…I want to pocket separate holes and the. V carve along the lines, how do I make this happen.

Hope I make some sense to someone, thanks in advance…

Gil

Advanced vcarve is only available if you have a BitSetter. You need to check your post processor is set to Shapeoko for the prompts to be issued for bits, bit changes and the BitSetter to be utilized. If you selected Basic gcode or GBRL you will not be prompted for bit changes and the BitSetter will not be utilized.

In Carbide Create go to the Edit menu and select “Select Post Processor”. After selecting the correct post processor edit your tool paths and re-save them to get the proper post processor in the gcode.

Thank you, looks like I am gonna have to run the whole program again? I changed the post processor, will I need to change it back to basic g code when I am done with this file?

If you have a Shapeoko why would you change it. The Shapeoko/Nomad makes use of the features of a C3D machine. The only reason to use the Basic Gcode/GBRL would be if you had a 3rd party machine and wanted to use the free Carbide3d Create.

Leave the post processor on your machine type.

Do I set the vcarve depth the same as the pocket? Thanks

There’s only one depth to set — it will be used to limit the Advanced V carving depth, and the depth of the pocket clearing will be set to match.

Awesome that’s what I was thinking but thanks for the verification…I certainly need it!

So, I’ve had so many different issues running the advanced vacarve… the last one I ran the pocketed area, about 2 hours and it didn’t ask for a bit change. I would like to run the vcarve now, do I have to start all over or is there a way to just to the vcarve so I’m not wasting 2 hours…

Any help again Is appreciated

If the pocket clearing operation completed it should work to just clear the checkbox, regenerate only the Advanced V carving portion, then run a file w/ only that toolpath.

I will give that a try!!! Thanks, I will run it again this evening… I will let you know… Appreciate you

So I did the pocket… I then unchecked the box for pocket… I set it to run the vcarve only as suggested. I am running with a 60 vbit. It has gone deeper that the pocket already and it still has another 21 minutes to run… I stopped it because I am afraid it will continue to go deeper and ruin board -#4…

Any advice, recommendations would be greatly appreciated…Again!

If the machine is getting deeper during the cut check your wiring — if you don’t find anything obvious to address send photos of your Z-axis motor wiring and wiring extension connectors including at the controller in to support@carbide3d.com and we’ll get this sorted out.

does your 60° vbit has a flat in the tip ? Probably not, but if it does you need to take that into account and zero slightly above the stock surface to compensate for the “missing” pointy tip.

@Julien this (mathematically) makes no sense. While your statement is true, if he’s set the tool lengths correctly on both tools, and the G-Code is outputting the same depth for both tools, even a Vee tool with a small flat bottom should cut at the same level.

If anything, with a flat bottom the pocket should end up slightly larger than programmed, but not deeper.

If CC is assuming that all Vee tools have sharp pointy ends, then what you’d need to take into account is the diameter of the flat bottom, and offset your toolpaths inward half of that diameter to get the correct dimensions in the finished part.

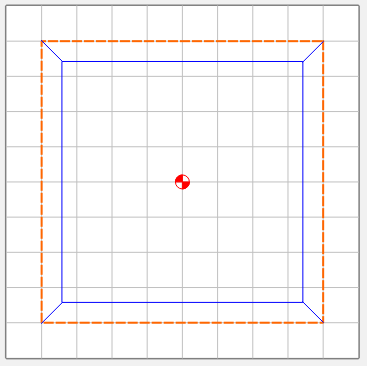

I created a simple example in CC,

and analyzing the G-Code noticed that 2 of the corners are being cut in a downward direction, and 2 in an upward direction. I would expect to always want to cut upward??

It only allows me to set one depth.

Yes, that was my point. Both tools should be cutting to the same depth. Regardless whether the Vee tool is sharp or a little flat.

Either the tools were not set to the same zero, or the machine/tool is slipping.

A quick check would be to touch off to the top of the part and check the Z value.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.