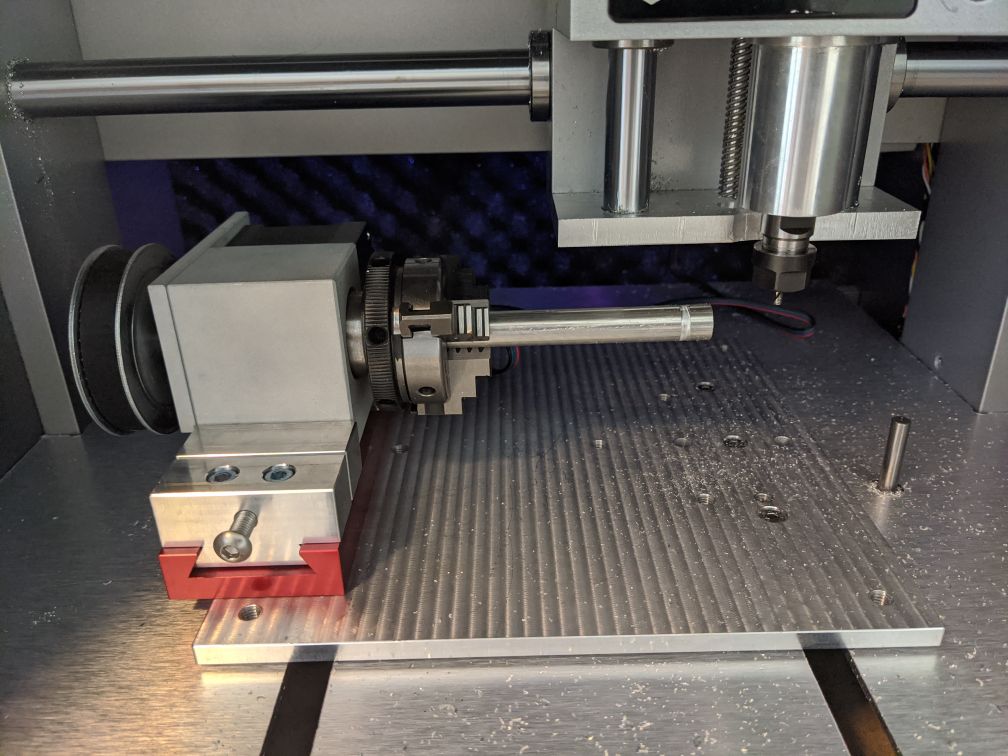

@RichCournoyer you asked for 4-axis photos and I can finally oblige!

I just finished all the electronics (soldering the third PCB after killing two previously, adjusting and flashing the firmware, making sure nothing exploded) and haven’t got around to making a proper mounting plate yet but I put the thing in the vice just to be sure I can actually cut stuff

So here it is:

And here’s a short clip of it running.

I was afraid the motor wouldn’t have the holding power to deal with milling metal (it’s listed as being for “wood working”) but it holds up without any issues.

Not bad for a $120 upgrade

I wonder, am I the first to add a 4th axis or did someone beat me to it?