So we compare apples to apples, what did you price? Size, thickness, aluminum or steel, type? It is also clear that you are buying one so no quantity or client discount. The tariffs on aluminum in the US also increased the cost significantly, ion fact the tariff increase also had a ripple effect on prices in Canada and I suspect other countries.

I priced quantity (2) 1/2" X 19.75" X 42" ATP5 aluminum (identical to what ohio diesel is using) from here. This is for 1 set, shipped to chicago from what looks like minnesota.

Cost per piece is $130.92 X 2 = $261.84 plus $54.20 estimated shipping is $316.04 total. (But again, you would need to do all the milling and tapping etc… this is just the plates.)

Garrett, Did you decide to move forward? I’d be interested.

Hey Jon,

Yes I have. I am currently waiting on 2 “prototypes” (They should come out perfect). The bed should be held to plus or minus .002 flatness. I should receive them by March 15th. I have a listing on Ebay to get a feel for the traffic. https://www.ebay.com/itm/143148749326. I’ll update the listing with actual images of the finished product. Once I get my hands on them and they check out, I will most likely doing a larger run. Hopefully I will be able to bring the total to $400 or under.

Keep us updated please.

Thanks for the update. Please keep us posted. I’m very interested in getting one. I actually saw the eBay posting yesterday but didn’t realize it was you…

I’m curious about the orientation of the seam between the two sections, I’d think front to back would make more sense, to keep the two halves coplanar. Can’t these sag or lift at the seam?

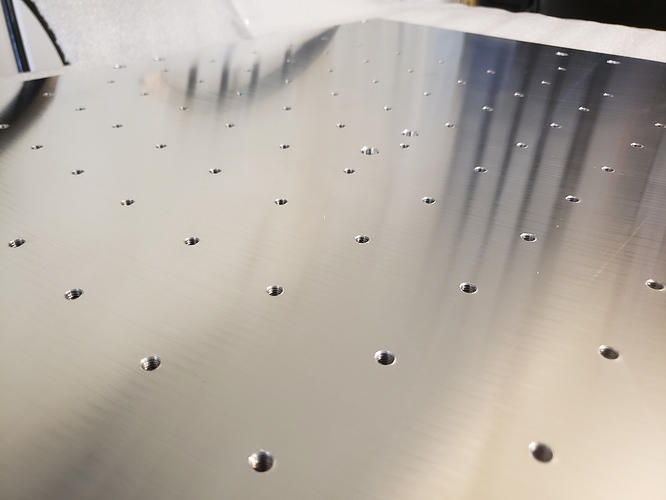

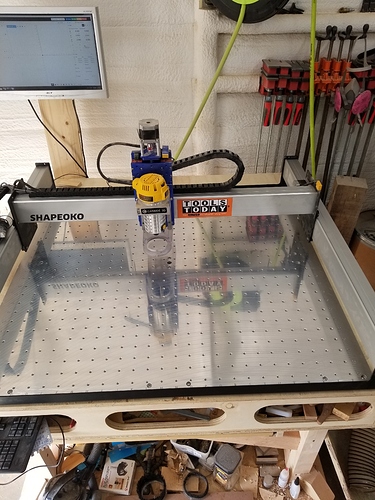

Hey Jon. Update for you guys. The 2 prototypes came in absolutely perfect. I have installed one of them on my shapeoko 3 of course. So far I have my bed dialed in to about 2 thousandths of variation across the entire bed(that includes variation in all of my axis). I am planning on taking the other prototype to my local university to use their giant precision granite table to see how flat the table actually came out. Im guessing less than 2 thou! I’ll post some of my chip cutting with the new table later

Well, I guess the money was burning a hole in my pocket. Carbide’s came back in stock so I purchased one. Now to level and square everything to the new bed.

Hey gents!

So whats the consensus, 1 piece or 2 piece .5" alum plate for base?

Thanks

I used a 2 piece aluminum plate (from a source I won’t mention due to incorrect flatness specs and improper shipping packaging.

What I experienced was aligning the 2 plate halfs on the same plane (top). The OEM strap brackets (3 each) are NOT capable of handling the additional weight of the 0.5" aluminum plate. Also, the strap plates are stamp steel and are not straight.

My issues are but unique and may differ from others since the aluminum plate halves arrived damaged by the shipper and also attributed to the supplier for improper packaging bowing of the plates from nylon strapping force applied. This was a 2 times repeated delivery and I had no other choice but to keep the plates as I had to press on for an upcoming project (wedding).

What I had to do was get rid of the OEM steel strap bracket and replace it with 80/20 aluminum. I also had to make the 2 aluminum halves on the same plane which was the tricky part.

This required building the assembly upside down since the top of the aluminum plates will be referenced to the same plane.

Then I added shims to fill in the gap between the 80/20 and aluminum plate and pressed on with the build.

Another issue I had was that the OEM design used a 3/4" MDF as the base plate. The aluminum plate is 1/2" thick. I also added an aluminum spacer between the aluminum plate halfs and the bed frame bracket to make up for the difference in loss height.

My reasoning for the aluminum spacer was 1 of many reasons but my goal was to stay within the OEM design height.

Here are some of my thought process of reasoning; Z axis travel falling of the rails due to an additional travel, aluminum plate below the bed frame didn’t allow for stock to extend beyond the bed frame, if using a spoil board need a thicker board.

Also the aluminum plate had 5/16" pre tapped holes. I wish I had gotten to 1/4" pre tapped holes. Most after market accessories like clamps and hold downs are designed around the 1/4 bolts.

After ALL the above issues and if I were to do it all over again, I would make sure that the supplier package the product better. Just like how Team Carbide 3D packs their product, USPS, FedEx, USP and any other Carriers marine proof for safe delivery.

Would having 1 full size plate have been better too so you don’t have to align the two sides? Maybe you should mention the company so people are careful if ordering from that supplier.

I had an issue with the company, they did sent another plate. The first plate was packed by wrapping a Home Depot card board box around the HEAVY aluminum plates. UPS dragged the heavy package and damaged the plates. The second set of replacement plates were protected by a wood perimeter, only this time the company used nylon band straps and strapped it as tight as they could and bowed the plates. Flatness specs are listed more accurate then what the mfg of the ATP 5 specs the flatness tolerance to be.

They should have taken a packing lesson from Carbide 3D. Even their lightest accessories that I received from the folks at C3D are packed like their heaviest Shapeoko XXL to survive any abuse from any carriers … Good job C3D.

In either case the company did their best to make it right and I did mine to make it work. In the end, it was a very expensive mod but well worth the added $$$ and frustration to see the projects that were output, put a HUGE smile on my daughter’s wedding and the most gratitude of her wedding decor from both the guest and the venue.

I didn’t think the company would have taken another shipping lost and I was running out of time, so I bit the bullet and made it work …80/20 ribs to pull the bow straight.

That would be a better option but of the large size for the XXL, I was informed that it would take a huge CNC machine for the task. Hence why its mfg in 2 plates setup.

From my experience being a newbie to CNC routers, it was challenging learning what to do for a mod and dialing in the squareness and flatness requirements.

But because I did a mod to the XXL and output several projects, I can now say that a 1 piece plate would be better served. I can also save $$$ by supplying the XXL size to the ATP 5 mfg and have them cut it and I put the holes I need using the XXL to do the milling.

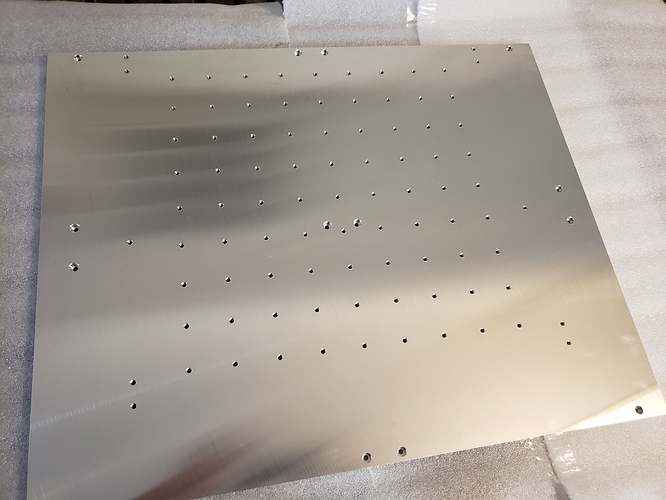

This is a plate from midwest steel and alloy, it is 39.5 x 42 x .625 and I love it!

I agree that 1 solid plate is a better option whether its mdf or whatever material…

that being said, I also dont think its necessary to go the route to mill 676 1/4-20 holes into the plate but… I also have the luxury of working at a machine shop. I will not have to worry about mounting locations although 90% of the time I will have a sacrificial wasteboard bolted to the aluminum bed. I had some time this holiday break and I bought 4 36" t slots to bolt to the bed with 3/4 mdf in between them, ill try and post a picture tomorrow.

If you have the means, go for it… if you dont I would not go with 2 plates if possible…

Hey Agentwusabi, did you buy the Mic6 or just regular .5" aluminum?

I bought the atp-5 plate from midwest steel and alloy

https://www.midweststeelsupply.com/store/castaluminumplateatp5

Did you not have any warping? I picked up a piece and it was warped pretty bad:(

No, I didnt… Mine came in really flat. what thickness plate did you get? and was it the atp5?

It was .5" 6061. Is atp5 the same as Mic6? If so, no it wasn’t:(