I don’t think this is really “attempt to limit torque” - it’s just inherent in the design. Torque is a factor of current spindle speed AND size of the mosfets because of the distance between poles. DC motors are efficient, lightweight, compact, and low maintenance. And have very peaky torque curves. This is why if you’re used to cordless tools and pick up an AC drill you’ll think it’s gonna tear your arm off if you try and use it to drive a screw. An AC motor is still a better spindle across a wide range of RPM. Ideally in a spindle you want 100% of torque all the time so you can set feed and speed on RPM and tool, not force yourself into 3-4+ variables.

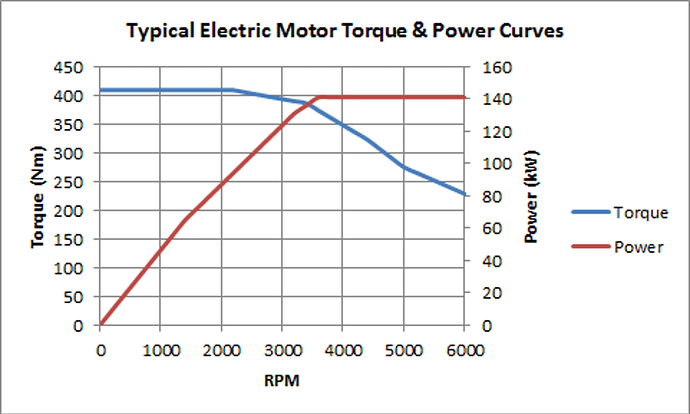

Here are typical torque curves for DC and AC motors. AC has the big advantage of highest torque available at low RPM, which simply can’t be done with a DC motor.

AC - notice how maximum torque is available from zero rpm. Wish I had a manufacturers chart, but this one is typical of shape.

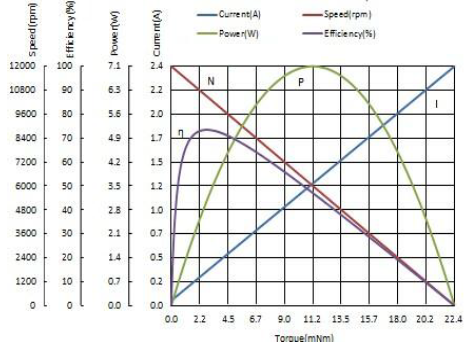

BLDC - notice how peak torque is in the middle of it’s running range, and very low at low rpm (and high).