Cutting board plastic.

Coriander would also be a good choice

I’ve done similar signs, but I place Avery high reflection self adhesive vinyl over the numbers and trim to fit. Fire department was amazed at how reflective it was and how easy it was to find my house

Additional: remember to check local codes for number size. It’s 4" here

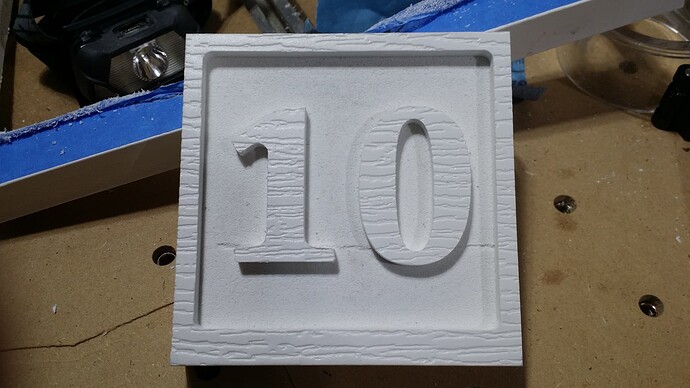

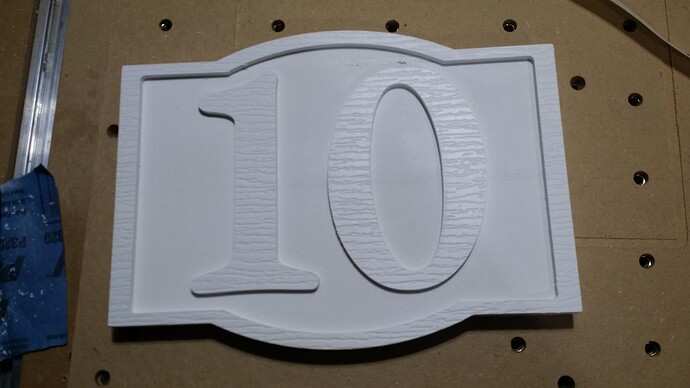

Im hoping i can get a little more help here. I took a stab at making some house numbers out of the .75 pvc trim board i bought and while the carving is going well for the most part, i keep running into a issue. The problem is i keep ending up with “cracks” for lack of a better term in the pockets around the raised numbers. Its most noticable in the small test peice i did but it showed up in my proper sign above the 0 as well to a lesser extent. Im not sure if its noticable in the photo but theres a faint line running through the center of the sign that feels like it will start breaking away if much pressure is applied Does this sound like its just flaws in the pvc, or an issue with the way its being carved. Currently using a 1/4’ 2 flute upcut bit at 75ipm 18000 rpm doc .05 total depth .190.

There are a couple of types of PVC trim; cellular and solid. The cellular product is less expensive and much lighter weight, at the expense of the middle being foamed PVC prone to occasional voids and inconsistencies. This is not usually an issue for trim work but stinks when you hit a void in your carving. Check to see if your local store has both available and try some of the solid core.

Look at it from the side to see if defect is all the way through. Just looking it seems like a defect in pvc.

It doesn’t look like the defects are visible along the side of the material but after looking at it a little more closely, you can definitely tell the middle of the material looks and feels different. Almost spongy in consistency so i must have cellular pvc which i guess isn’t ideal for what i’m trying to do. I think i’ll go back to my original idea of just doing cut outs of the numbers instead, I think that may be the smarter move with this sort of material. Thanks again to everyone who helped me out with this.

I agree. Looks like voids in the PVC board, not anything you did with the cutting. Try a different brand of board. I always use Royal Building Products and have never had this issue. I always use the flat side when cutting but i like the look of the side with the wood grain pattern.

PVC is a good choice, paints well, weatherproof and easy to cut

I gotta believe you could patch the defects if they are aesthetically undesirable.

Perhaps a similar technique used to patch exotic wood, where you use the dust from the actual material mixed with a little binder (glue, epoxy…). White caulk or maybe even white Bondo (poly resin) might work too.

I have a bunch of PVC scraps in the garage, I’ll see what I can come up with.

One more thing to try. Try a new bit to make sure the bit is as sharp as possible. Could be if the bit is not sharp it could be pulling soft spots from the PVC instead of cutting through it. Just a thought.

Thanks for the suggestion. I’ve only run a few jobs prior with the endmill so i think it still pretty sharp but i’m going to try again with a fresh bit just to be on the safe side. I think ill go with a slightly shallower cut as well just to see if it makes any difference

Years ago i made some for a mailbox out of Corian countertop material with a router and they lasted for several years with no discoloration or blemishes. Corian is easy to cut and makes for a nice project. I recently made new ones with my Shapeoko Pro because my old routered numbers were not the best quality cuts. Just another idea that i haven’t seen anyone else try.

This topic was automatically closed after 30 days. New replies are no longer allowed.