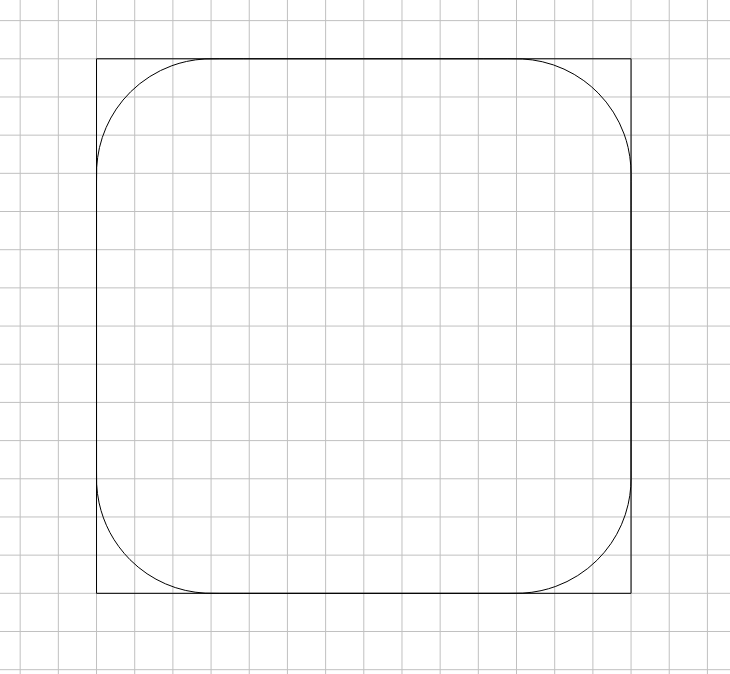

Hi - I’m trying to create a 45º bevel cut on the outside edge of a square piece of 1/4" stock, for use as the bottom of a box. I’m hoping to CNC this rather than use the router table so I can get radiuses on the corners. I can’t get the vcarve option to work, as it shows ‘empty toolpath’. Was going to treat it like a contour cut instead, with the 90º v-bit. Does this seem like a good way to go about it? Is one required to use the vcarve option when using a v-bit, or can one just use whatever toolpath option seems to work for the job? Thanks in advance.

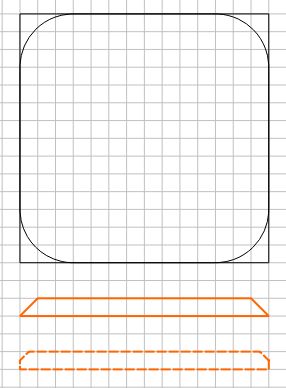

yeah contour cut with no offset can work for this. for something like this a finishing pass will work well. So if you have 0.25" material thickness, you could do something like 0.2 (or 0.1" steps if you want to be conservative) then the final pass will only take a 0.05" pass and should give you a nice clean edge.

Terrific, thanks for that. I’m still figuring this stuff out, and appreciate the help. So just because a bit is a v-bit, that doesn’t lock one into using only a v-carve toolpath then?

no as long as you pay extra attention you can do whatever you want mix/match bits etc. adding a chamfer to the top edge with a v bit is a good use by restricting the depth and adding an offset for example

Are you looking for a full bevel, or a chamfer?

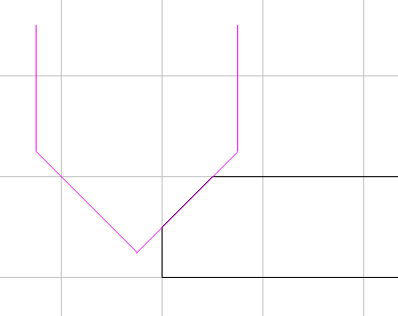

It helps me to draw a section view to make sense of what’s going on.

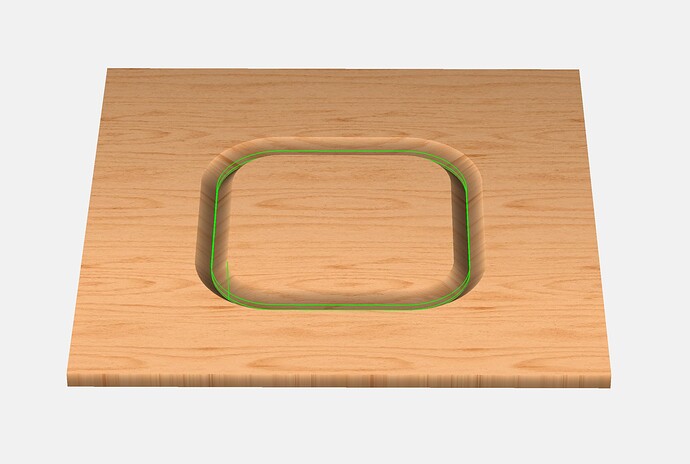

For a full bevel, then yes, contour - no offset - 1/4" deep on your current vector.

To chamfer, I prefer to avoid cutting with the tip of the vee-bit. so I might offset the vector by 1/16", then contour that with a 3/16" depth.

For a V-Carve, or the vee cut on advanced V-Carve, it will only let you select a Vee bit.

I believe all the other paths will let you select whichever bit you want.

For the advanced level, you can program it with one bit, but then load any bit you want in the machine. You just have to have a good imagination since the simulation won’t look like the final result.

For example, a round-over tool can be programmed with an end mill that is the diameter of the lower ‘nose’ of the roundover tool, the small diameter at the end of the tool. Simulation will show nothing, but the finished part will have the rounded corner.

Actually, there was an update a while back which enabled getting a 3D preview when using a V endmill for contour toolpaths (they also work in Drill toolpaths for spotting).

Thanks for that; will be doing a full bevel, and this is a test, working up to a bigger Amana bit that can do 3/4 inch deep on the bevel for thicker stock. I’m assuming that if I keep the plunge amount low, it should be able to handle anything my router can (please correct me if I’m wrong!).

I did notice that the the preview looked right, at least to my untrained eye.

It looks like pocket paths will also show a decent representation with a Vee bit.

But if you program with one tool, and then use a different tool on the machine, which can be a tactic to get functional paths with unsupported tools, then the simulation won’t be accurate.

I guess it’s a choice between just getting useful toolpaths, or having a simulation that is accurate.

I will often create pocket paths to remove material for the simulation, but then disable them & just use the contours to cut.

This topic was automatically closed after 30 days. New replies are no longer allowed.