I do a lot of double sided cuts so tend to use dowels a lot for aligning the second side. The strategy for zeroing the second side is usually:

- Cut first side and remove the material. This is the first work coordinate system.

- Cut the holes for the dowel pins on the second work coordinate system for the second side. Zero for this WCS will be center of one of the holes.

- Place pins, flip and place material and resume cuts for the second side in the second WCS.

This works great, but I’ve streamlined it recently to reuse existing holes in a custom jig. The custom jig uses headless, threaded locating pins. For this process, step #2 above is replace by using the bitzero v2 to zero on one of the pins (can’t zero on the holes since they are 8mm and non-metallic.

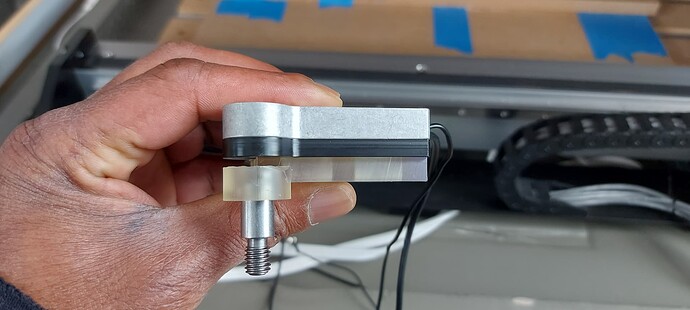

To allow Bitzero to zero on the locating pins, I created this jig to align the bitzero with the center of the pin: