I just bought a Shapeoko 5 Pro in May and haven’t had the chance to set it up yet. Upcoming surgery, anyways, because I am such a newbie and I still have so much to learn yet, I bought all of those. Now it seems that I don’t need all of those. Could someone please explain why (layman terms since I don’t have the ability to set it all up for 2 more weeks)? I know what the Bitsetter does but after that I’m lost. We do need to update our plumbing & electric in our home/garage. Our home is about 75-100 yrs old. I will be using the Shapeoko in our home since the electric is terrible in our garage and our garage needs repairs. Also, any suggestions for good dust collection on a budget?

I appreciate the help.

There are a couple of considerations here:

First, all the documentation for everything you need to know should be at:

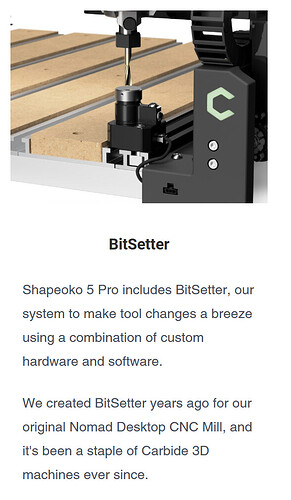

- the Shapeoko 5 Pro includes a bundled BitSetter as noted on the Shop page:

so it should not have been necessary to purchase this as an add-on — just use the bundled one — if you purchased a separate BitSetter, check in w/ the folks at sales@carbide3d.com to arrange for its return.

The BitSetter will be used to manage tool length offset when running files with multiple tools, or when changing from the probing pin used with the BitZero (see below) to the tool which you will be cutting with.

- the VFD Spindle and BitRunner are redundant, and it’s not possible to connect both at the same time, one should use one or the other.

The VFD spindle is an integrated unit which affords on/off and full speed control, but requires that one mount and wire up the VFD as well as the spindle per the instructions:

https://my.carbide3d.com/manuals/vfd-spindle-kit

The BitRunner is intended to turn a compact router used as a spindle on/off (and does not afford speed control). If you have a VFD you do not need it, and may return it as noted above.

Some folks purchase both a VFD and BitRunner intending to use the latter to turn a vacuum on/off — this won’t work, and it’s best to have a setup where the vacuum is turned on in such a way that it won’t power up at the exact same moment as the spindle — a current-sensing device such as:

https://www.amazon.com/gp/product/B085NH2LC9

is the recommendation.

- the BitZero is an optional accessory which automates setting zero relative to rectangular stock at the corners, or on a flat surface — it works best with a probing pin rather than a tool, so has the afore-mentioned synergy with the BitSetter. See:

https://my.carbide3d.com/manuals/shapeoko-bitzero-v2

I think it’s nicer to use a machine in a conditioned space (my machines are all in my basement, and when I get another Nomad it will go into my son’s bedroom closet). Note that if you do want to put a machine out in the garage and if you need to re-wire it the VFD will not work on a GFCI receptacle, so you will need to wire things up so that it has a normal outlet.

For the electrical wiring, it is best to have at least two circuits:

- one for computer and machine

- one for spindle/trim router and vacuum

Three circuits is ideal, allowing one to put the trim router and vacuum on separate circuits. Note that there are two separate sides to a typical panel, so it is best to arrange to have the computer and machine on one side, and everything else feeding from the other side.

The usual affordable choice for a dust collection setup is a shop vac — but be sure to spend enough to get a reasonably quiet unit which is reliable for running for hours at a time w/o overheating (when I was first starting out I used a pair of home vacuums and just switched them when one overheated) — Fein or Ridgid are the usual brand recommendations and a cyclone setup such as a Dustopper or our Mullet:

For other considerations see:

and

https://old.reddit.com/r/shapeoko/wiki/gettingstarted

If you have any further questions, feel free to ask here, or at support@carbide3d.com

I guess you have to do what you have to do but running any CNC inside a house is very bad. These machines make dust tornadoes even with dust collection. So if possible I would make an enclosure for the dust but also noise. CNC machines are very noisy and will disturb your other residents.

Good luck with your surgery.

We will be making an enclosure at some point. CNC will be quieter in the room we have setup for it. We want to move to a bit warmer (not too warm) next Summer or Autumn if we can. We have been looking for a long time. We have a place in mind but we’re waiting for the house to be put up for sale. They said sometime next year they hope.

They haven’t sent the bitrunner yet. I just bought the bitrunner, along with some bits, yesterday/Saturday afternoon. It’s more of the terminology that is harder for me to get right now. My husband and I have never used a CNC before and until recently we’ve never used a miter saw, trim router and so on. My experience building was based on affordable tools back in the 90’s. A Skil saw, jig saw, a few hand tools, and I’m sure you get it. I used my tools mostly for home repairs (both light & heavier repairs), remodeling, and some smaller projects for gifts. It’s been several years since I had to stop to now. My husband has had less. I am not well versed in in computers and know nothing of code but I have been trying to learn. This is all new to me is an understatement. I didn’t know about the VFD Spindle until this April. I bought what I bought on recommendations from Carbide. We had to get it this year because we had the extra but it’s rare for us to have enough $$ so that is why we have it now and not later in case you may be wondering. I am not upset, just embarrassed for not understanding things clearer. So with that, what I would like is to know whis what is the purpose of the bitrunner? I have read it but comparing it to the VFD is what eludes me. I’m sorry for asking, I should have researched it more heavily first. I will go and do that again on google. I just didn’t see an explanation on Carbide that would help my understanding. Thanks for your help.

If you use a trim router, and don’t have a BitRunner you would need to manually turn the trim router on when the machine first starts cutting, then turn it off when the file is done, or when you need a tool change (and back on after a tool change) as well as manage the speed using the dial.

If you have a BitRunner, then the BitRunner will turn the machine on/off as necessary, but you will still need to manage the speed using the dial.

If you have a VFD, then it will do on/off, and manage the speed.

Please contact the folks at sales@carbide3d.com about the BitRunner.

There shouldn’t be any need to do code — it’s just a matter of drawing up geometry:

and then assigning toolpaths:

If you will provide us with an example project/file we will gladly walk through it with you.

I was able to get the explanation I needed to understand exactly. I don’t believe that I understood the Bitrunner enough. I thought it control more. Sorry if I complicated anything. I can over think things at times.

I will send an email to Carbide tonight and call tomorrow to ask if they can cancel the bitrunner. Thanks again for your help.

Please send us an e-mail at support@carbide3d.com and we will do our best to walk through this with you.

I get it now. It is beyond simple. It’s probably why I didn’t get it at first. Hence the over thinking. I just need them to cancel the Bitrunner that I ordered before they send it out.

This topic was automatically closed after 30 days. New replies are no longer allowed.