Finally got everything in place to route some Aluminum with the Dewalt. Made this fine piece with the 2L Single Flute Diamond Coated Endmill @Vince.Fab suggested:

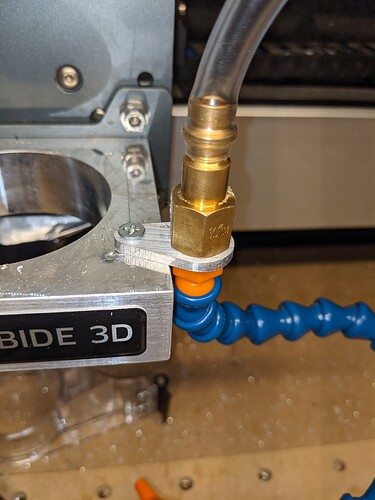

(Yes it is a silly little mount for my air blast line)

Then when the cutting was done managed to do this:

The wire got caught in the HDZ while it was retracting. Luckily the spindle was off when it did that. Reminder folks, proper wire routing is your friend.