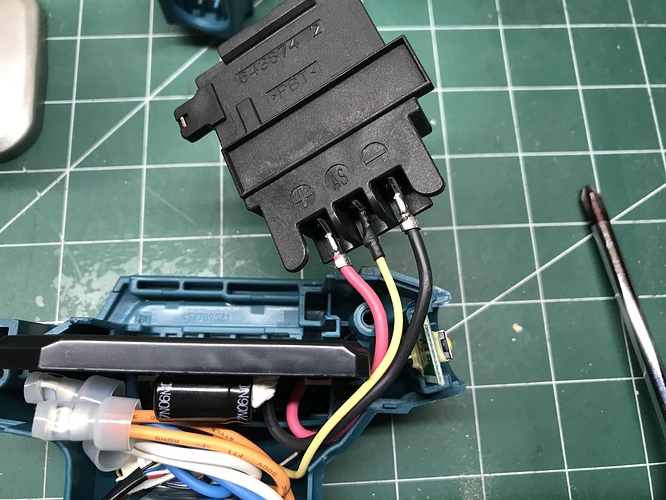

@Vince.Fab so, I connect red and black to the power supply. What about the yellow? Just leave it there?

@griff “AS” to positive as well sir.

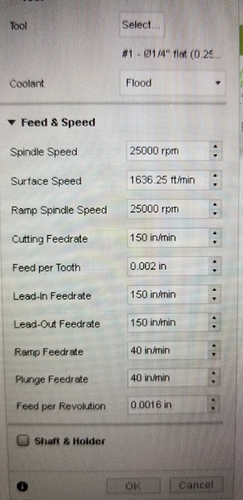

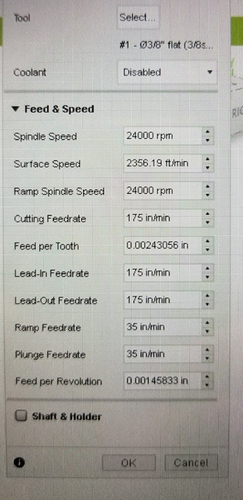

The max speeds and feeds on the TAS will largely depend on your machine and setup ridgidity. I run close to 2000sfm on 1/4 and 2300sfm on 3/8s with microdrop ensuring lubrication and heat management. Usually run a minimum of ipm of 150-175 and 1.7-2.4 on the modded s3. Manufacturer recommends a 3 thou chip but we cant go that hard lol.

On a stock s3 I’ll keep it at 75ish ipm and 1.3-1.7 thou chipload to keep chatter under control.

@WillAdams imo it would be more effective adding a 5th bearing support to counteract leverage. I know I’ve had quite a bit of luck with that method. Thinking about trying a different style linear rail.

Im trying to get an electrician in here today to measure voltage and amp draw.

@Vince.Fab. Ok, cool.

I don’t know if you’ve noticed from my pics that I have an hdz, albeit home made from @Luke’s plans.

Right now I’m chasing down some chatter in +Y adaptive, 10mm doc, 0.3 load, 1500 mm/min, 24,000 rpm. When I get that fixed I’ll chop up some ali with the AC Makita to get a baseline then compare to DC performance.

Maybe if we both work on the same parts, toolpaths we’ll learn more? I know I will, haha!

So your router speed is 30,000 RPM for 1/4" and 24,000 RPM for 3/8"? Wouldn’t your chipload with the 1/4" cutter then be 0.83 - 1.04 mils? What depth of cut do you use for each machine when slotting? Are you cutting 6061 T-6 aluminum? Are Lakeshore’s speeds and feeds for the usual DOC = endmill diameter?

https://share.icloud.com/photos/0OzZA_b1Hn2x1AMmY1hR2MaKw

I wonder if this link will work?

All connected up, ran it briefly on a 6S (22v) LiPo. Stay tuned

This link shows router at full power. Now if only I had a watt meter

https://share.icloud.com/photos/0ODwB2ZGcsd1Q-wzj7zHxfDVA#Home

Oops, amateur day, hit slow mo

Griff is that’s a 3/8s running I would say you are playing with fire at that chipload, looks like 0.83 thou. At 24k rpm surface speed is already a little over max recommended. If you dont take a big enough chip it wont take the heat with it, and melting AL to your brand new TAS isn’t good lol. If you have a test part I’ll gladly put some hours into machining so we can compare. I doubt you want to machine my parts lol

@gmack

These are my default TAS settings for modded s3, usually stay within 20% depending on a few factors. I also try to stay away from plunge or full diameter slotting if I can. Usually those are my final contour cuts to free parts from plate so I’m pretty conservative. I’ll take a 0.015-0.030 full width doc depending on stickout and estimated deflection.

When rpm changes so does travel speed to maintain chipload. 30k rpm on a 0.250 is 1963.5sfm, my goals are to hit 200-220 ipm reliably in the future with a 0.100 DOC after a few more upgrades. Router vibration also plays a role at these speeds. I recommend running through the rpm range unloaded with an rpm meter to find out what your “smooth” high speeds are and program to those.

Good thing I’m practicing in white oak!

How are you liking the brushless, Griff?

No experience yet, waiting for power supply.

Power supply received, 24 volt/500 watt. Voltage dialed back to 20 volts.

Material is white oak, TAS 3\8”, depth of cut 7 mm, load 1.5mm

PS cool to touch, Makita slightly warm, 8 minutes to complete cut.

How is the noise levels on these brushless units?

The same I’d guess. 91 dB 2 feet away. 62 dB with door closed, 3 feet away.

Acquired for testing and given a quick run down on how to use it. Anyone have any guesses on real life amps/wattage???

It’ll be interesting. I have some 900 kv motors for quad copters that draw 20amps continuous and 40 or more in bursts.

Maybe 15 amps or so? Wild ass guess

Can’t guess without more details. I.E. material, axial and radial width/depth of cut, spindle speed and feed rate.

Heavier adaptive 25k+, 150+ipm, big chip loads. I’m going to try to push it as hard as it will take. Haven’t broken anything in awhile lol

That’s quite a bit of power Griff! I have an E-longboard with a 2.2k that only pulls 30amps max…but the ESC is also fully programmable

Those beer cases are heavy, need some grunt to fly ‘em around the block.

I think my largest heli runs somewhere around 90 amps peak on 6S 2200. Blade span around a meter across I think? Would hate to get hit by that!!! Bet it would make one heck of a spindle…for about 6 minutes, ha!!!

Dan

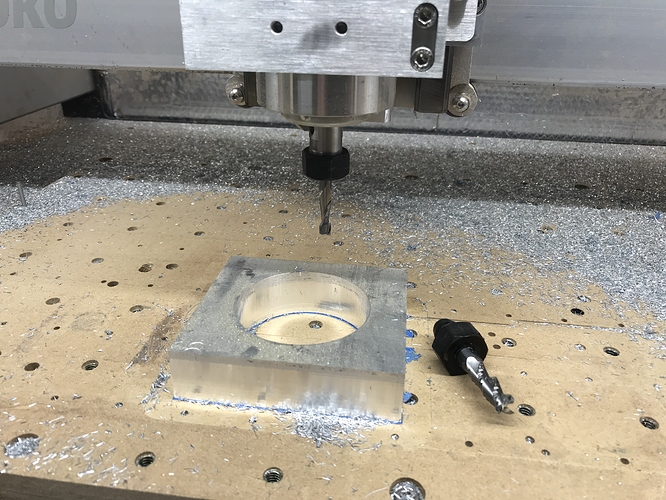

A little evaluation run in ali. 1” block, 65 mm hole, hmmm I wonder what this is for?

Used a 3/8” TAS for the first time in Ali, then a 250 2 flute generic, both per @Vince.Fab recommendations above for stock Shapeoko.

Router and power supply cool, calm and collected.

This is looking like a very attractive option, I have been eyeing a 1.5kw ER16 Spindle on Ebay, to get the 3/8 collet size. The 18v makita is slightly less in cost, but do you think a speed control could be added to change speed via gcode?

Thanks for sharing your findings guys, awesome for the rest of us!