So, as promised, here’s some thoughts on how you might put together a reasonably non-housemate aggravating Shapeoko XXL. I’ve been thinking about how I’ve quietened machines and rooms in the past and how those tricks might be adapted.

So, first off, an XXL in a 7 foot by 7 foot room;

In terms of approach, I’d suggest that we try to absorb the noise at source or stop it propagating out into the room, it’s almost always best to do this when you can isolate the noise source. I think this will also be helpful in sawdust containment, one guaranteed thing about milling lots of plywood and hardwood is that you’re going to make a lot of sawdust, not all of it will be captured by the extraction system and an enclosure will help keep the mess inside.

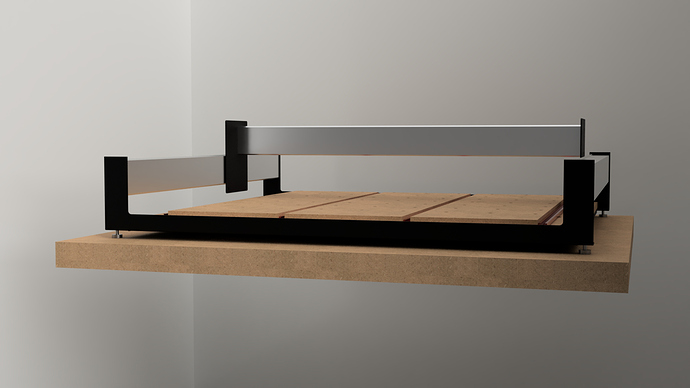

The first thing is a solid base for the Shapeoko to sit on, I’m in the process of bolting mine down to the torsion box bench to stiffen up the wasteboard and frame as advised by others here (sorry, can’t remember who). I built my torsion box way deeper than it needed to be, here’s a rough shot at a more suitably sized unit;

It’s a simple torsion box top and bottom panels held apart by braces, built with MDF or Ply these are stiff and tend to be quite dimensionally stable.

This isn’t isolated from the machine at all, it’s just a rigid support for the machine so you can tram it, level the wasteboard etc. from a flat consistent baseline.