Since I sill use sanders ans saws in my shop I wear earplugs all the time.

There are specialty solutions for safe sanding. Dust collection with sanders and grinders is entirely possible. Unfortunately, these solution require choices to be made at the time of purchase - it’s hard to retrofit.

In your situation I would recommend ear plugs (hearing protection) and a HEPA filter mask. Before ging inside your home I would vacuum myself off. Yes, vacuum your hair and cloths!

I am curious about what you think an adequate vacuum set up would be. I have been thinking about building a collection system for all my tools.

Safe air handling for enclosed spaces with friable material machining can be achieved via two solutions. Both of these are accepted by the EPA (US) and EU (Europe).

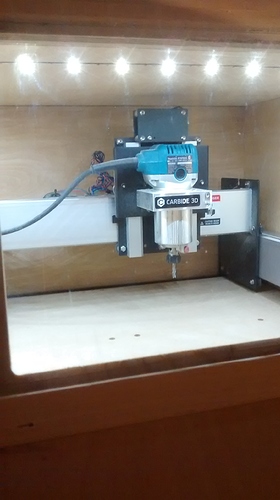

Start by having a dust head on your CNC machine. The dust head should have as large a vacuum fitting as possible. 2.5 inches is the effective minimum and 4 inches is required for truly safe operation.

A) Exhaust the air outside.

dust head → tubing → dust separator → dust collector → dump air outside → 5 micron filter

B) Exhaust the air inside.

Solutions A and B use a dust collector - a vacuum element.

dust head → tubing → dust separator → dust collector → HEPA filter → dump air inside.

With solution A a Thien dust separator or a cyclone is acceptable. The 5 micron filter is necessary to avoid the accumulation of “snow” outside.

Solution A tends to be quite inexpensive but has a downside… noise. The exhaust may bother neighbors. Depending on how sensitive the neighbor is, and how far away they are, it may be possible to install a inexpensive muffler to bring the sound level to an acceptable level.

Solution B require a quality dust separator. The Thien method is good but not as good as a commercial cyclone. The need for a super high quality separator is to remove as much of the particles as possible before the vacuum. The HEPA filter protects the user for dangerous particles but are relatively expensive. On order to avoid high HEPA filter costs, a quality dust separator is necessary to slow the clogging up rate of the filter.

Please note that dust collectors often come with “filters”. Most of them are dangerous to your health. Unless the filter is HEPA rated, one is unsure that they aren’t being cheated, potentially damaging their health.

How to design the tubing and such we can discuss. It’s not hard, nor is it expensive. Like enclosure design, a bit of thinking and understanding up front produces excellent results.

mark