Not that I know of, but one mitigation is to buy spare collet nuts (and collets), one per tool you are going to use in a specific multi-tool job, and prepare the nut+collet+endmill assemblies in advance. This way, tool change boils down to loosening the nut, swapping the nut+collet+endmill for the next one, re-fasten, done. Honestly, if this is too cumbersome/long for you, you will probably find yourself looking at ATCs (and that’s a whole 'nother can of worms…but there are some pretty impressive threads here on folks who did just that, for lots of monies)

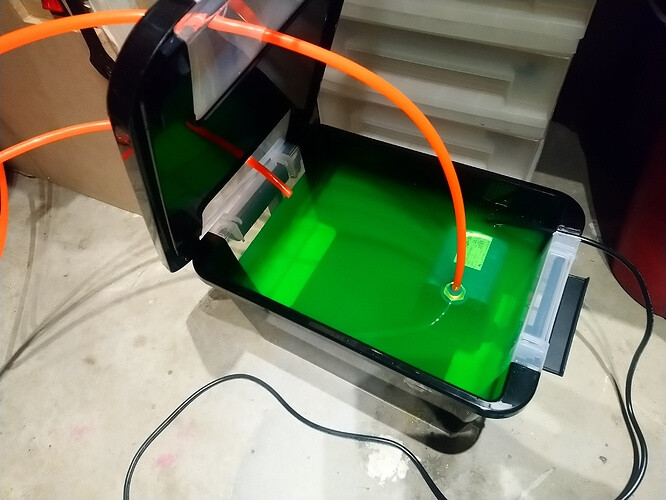

Water-cooling: it’s not that big a deal to install really. Like everyone else I started with a bucket of coolant with a lid and two holes in it,

and to be honest it worked perfectly, but the cheapo submersible pump that came with the spindle kit started to agonize so I decided to go the chiller way:

and it’s quite convenient too, so I would recommend it for a hassle-free experience.