I checked it is a 1/2 inch shank. Sorry.

Ah thanks for checking. Someone posted a $$$ one in this tread (110$!) But it MIGHT be worth it to us as we build this.

ZZ

https://smile.amazon.com/Whiteside-Router-Bits-1502-90-Degree/dp/B000A804DA

is not as $$ but is 1/2" wide.

now you can of course make 3 cuts with that to make it look wider (upto 1"), first make 2 cuts parallel to eachother at the 1/2" width of each side, leaving a little ridge in the middle, and then a 3rd cut deeper in the middle.

if you pick the right locations for the cuts the deeper cut stops and “continues” the side wall from the first 2 cuts

I think your “45” is usually called “90” on this forum, but yes I’ve seen bit manufacturers call them “45.” It can be confusing.

100%. I guess I lean on saying 45 as that’s the cut it ultimate creates. But yes, 90 degrees.

You cannot make a vector on a line in Carbide create, you need a closed vector. You could use a rectangle an go around or a rectangle that is only a mm or so wide so it basically is a line.

Contrary to what is being said here, I have made several very sturdy cabinets with plywood albeit I used glue and screws but no pocket screws. I made many boxes using 0.20in plywood, some using the 45 deg method and no screws or nails while others use joinery.

you CAN do a vector on a line in carbide create.

Well I stand corrected, I don’t use CC very often and it had been a limitation. I tried it it works but the simulation does not show a V-bit toolpath using a contour toolpath.

Correct. Unfortunately, Carbide Create won’t preview when using a V endmill unless it’s used for a V carving toolpath.

I’d give my interest in hell for a nice graphical tool which would do follow path operations using an arbitrary endmill with differing heights at various points.

sort of a hybrid between camotics and some of those gcode viewers?

or you mean on the cam side… a cam side tool shouldn’t be insane to build (almost a hold-my-beer but not saying I’ll build it)

Yes, something like that, but graphical, and able to import vectors and ideally allow for some basic vector editing.

I broke down and downloaded NCPlot again, so I’ll probably just directly hand-code the G-Code, which is really tedious in Grbl, but should allow me sufficient control — I’ll probably also try again in CAMotics, and if need be, I’ll try FreeCAD, or maybe work up an extension in Inkscape.

I was pondering an inkscape extension or post processor; I more or less am inching to having built a complete gcode generation toolkit at this point. If you’re ok with 2D and using inkscape … a small post processor is trivial

(in inkscape you can give a description to each line segment… turning that description into depth is easy)

Give me a tool which:

- can be scripted

- will allow one to select a path, curve, or arc and assign a beginning and ending depth

- use arbitrary endmills

and I’ll finally be able to get some joinery designs out of my head and off paper and out of OpenSCAD and onto the machine to actually make them.

(and yes, I know that that describes CAMotics — JavaScript is not my strong suit — as noted before, I’d want a graphic tool which would allow the import of geometry, the selection and control of it and so forth. I’ve made requests re: Carbide Create, but no idea what features might happen when)

Oh really? It can’t cut along a line without a closed vector/loop? I’d PROBABLY just try to make it 1mm wide…

I’ll post when I have a test done.

Good to know. I think I can make this happen without the preview.

The newer versions of CC allows you to run a toolpath that follows a line that is not a closed vector. I corrected myself after @fenrus pointed it out.

Ah cool. I’ll have to download it before attempting this…as I’m sure my version is over 2 years old.

Cheers!

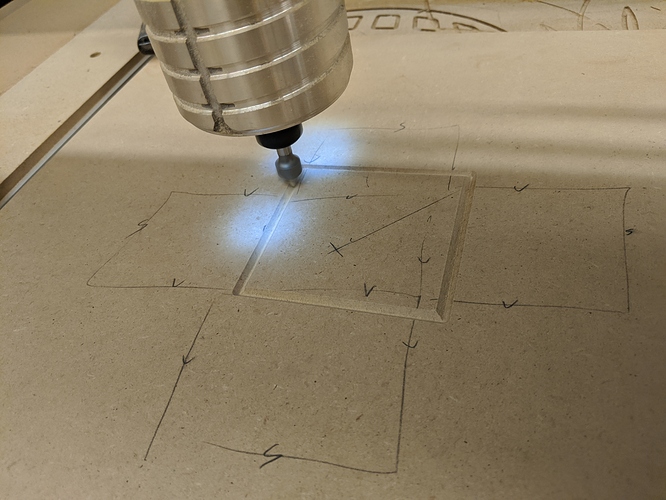

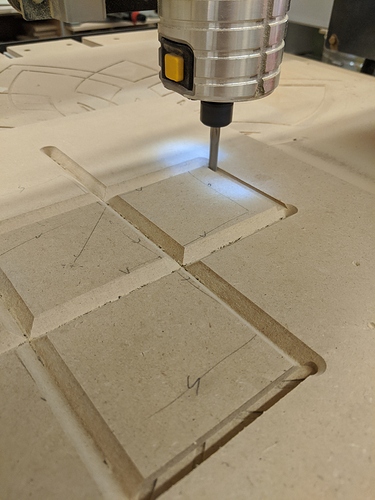

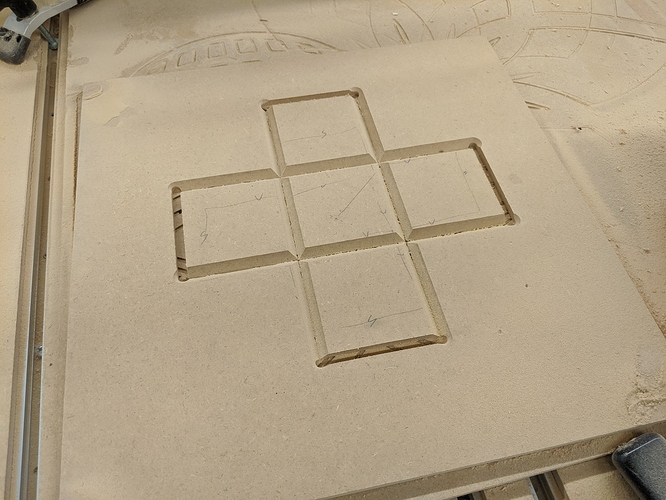

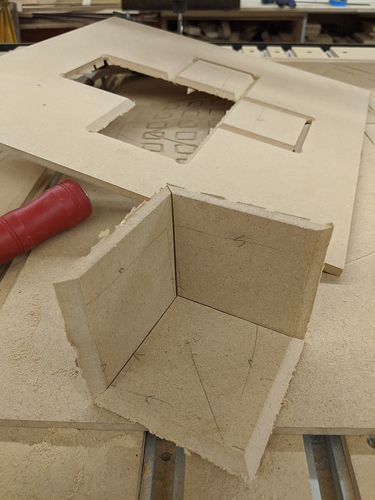

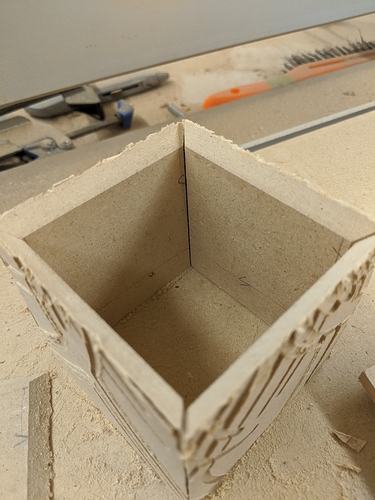

Did a test cut this weekend with some scrap wood. We’re aiming to cut 1/4", So I’ll need a bigger Vbit, but I think this will work for us.

I hope this can help someone in the future.

ZZ

If you leave an onion skin, you can just fold the pieces in place.

technically you don’t need a bigger bit, just more passes, but from a reliability/usability angle it’s much easier to get a bigger bit, and they’re not insane expensive