Yeah, I can see that - but then again, as is often the case with my cutters, if the cutter diameter is less than the shaft diameter (for example, 8mm shaft, 3mm cutter diameter), care must be taken not to exceed the flute length when fixing the cutting depth. Therefore it seems useful to be able to see the flute length of a given tool - in fact, the program could even issue a warning to indicate that cutting depth exceeds flute length, and that the mill can’t “dive” into the material any deeper than the flute length allows.

442 still wouldn’t let me edit a tool. Found the problem though. This refers to the Mac version. In Germany, the decimal separator is not a period but a comma. So, to indicate a diameter of four and a half millimeters, your average German will write 4,5mm. I had the Region preference set up to use the comma because that’s what my e-banking app needs. I found out in the Advanced Preference settings (OSX) that the decimal separator can be set differently for numbers and currency values. So, I set it back to period for numbers but left the comma in place for currency. Lo and behold, editing tools in CC442 now works like a charm (haven’t done a lot of thorough testing, but at first sight it looks very promising).

That’s interesting. This new code should respect the locale in the operating system and use a comma or period depending on what’s appropriate. (A German comma was the actual example in the documentation. ). I’ll have to look into that a little more.

Right now, Carbide Create will never pick a cutting depth that’s deeper than what the user entered. Because of that, the flute length would never be used for anything. (And in some ways, the cutting depth value is a proxy for the flute length)

Again, all of that could change, but that’s the thinking that led us to the current implementation. If this new build is well-received when it’s released on the stable channel, and most people seem to deal with the tool entry well, then I can see allowing more of the tool geometry to be defined.

I’m talking about user error - like me, trying to cut 15mm material all the way through with a cutter that has only 12mm flute length. Not gonna work. That was my scenario.

fix for my issue is confirmed fixed in 442… thanks for fixing!

Anyone else have this problem? AVG antivirus is saying the 442 .exe file has a rare virus. I tried it on two different computers–Win10 and Win7 systems–and I got the same result. I was going to run it anyway, but thought I’d check here first.

False positive.

Please check the .exe with a 3rd party virus checker such as

https://www.virustotal.com/gui/

so that you’re confident of it being safe.

Quick questions. Are the different types of materials going to be added, such as hard woods. because every time i go to my main set up. its always on acrylic even after i put it on MDF and save it.

Yes, we will eventually add the most commonly used materials.

For a preview, and some feeds and speeds to use, please see:

That bug was noted in our team communications and confirmed and will hopefully be fixed presently.

super nitpick on build 444: the tab order in the screen where you can edit cutters in your library seems messed up

Not sure what you mean, it seems to work in 445 ![]()

well I’ll be surprised, in 445 I can’t reproduce this either

One more thing I would really love to see: making the path to the tools database an editable preference (alternatively, leave the database at its default location but offer the possibility of automatically saving a copy to an arbitrary directory after each modification). That way one could store the database on a dropbox volume, thus avoiding the tedious step of manually copying it to the target directory if a tool has been edited or added on another computer on the same network. Happens to me constantly: I like to do tool editing in the relative comfort of an office environment on a desktop computer whereas the laptop is permanently located in the workshop.

The way vectric handles this (cloud sync tool library) is awesome.

I wonder if there is enough information in the c2d files to, on opening a file and seeing a new bit, ask the user if he/she wants it added to their library.

I tend to design in my living room and share the file with a dedicated small computer in my basement that controls my machine. Very occasionally I need to make small tweaks to the toolpaths in the basement, and not having the database sync’d causes issues… but you can either sync the database, or have CC just add new bits from the file you open if it does not know those bits yet (or if they are updated).

of the two, while syncing is nice it’s more complicated to build /set up / …

Just started testing the 445 build and all seems to work fine for me … I like the new tool database function and the ability to share unique cutters between my office PC and the machine controller system.

I am a HDZ user with a VFD spindle motor that I have wired to be controlled by the ShapeOKO controller. I would like to see a way to bypass the user input boxes … “Set router speed to …”, and the “Turn off router” boxes that I am now seeing for the first time. These are not needed when the spindle control codes are being passed thru the controller to the spindle controller, they only cause me another click to complete the machine cycle.

Also, is there anyway to delay the start of the spindle until after the user’s entry at the “Start cycle” box.

A big thanks to the Carbide 3D team for all the efforts they have (and continue) to support their products and FREE software. I am so VERY pleased that I purchased this machine instead of one of the other offerings. I could not be happier with the hardware and software being supplied by Carbide3D.

THANK YOU!

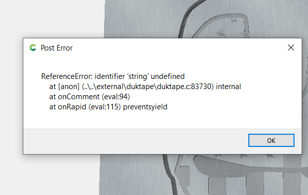

Very new so please be patient. Downloaded the beta seems to work although its slow. However when I try to save the GCode or send it to Carbide Motion I only get an error message. Regards, Derrick

Grab the latest beta from:

https://carbide3d.com/carbidecreate/beta/

That was a bug in the GRBL post that we fixed a few days ago.