was there a recent Mac version upgrade of Carbide Motion?

How do we determine the latest version and see upgrade notes?

was there a recent Mac version upgrade of Carbide Motion?

How do we determine the latest version and see upgrade notes?

zig zag papers work great no joke.

When will the next Carbide Motion update for the Mac be available?

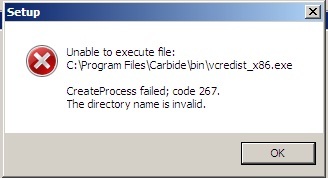

I’ve recently installed Carbide Motion Version 2.0.333 on two different laptops and received the same error near the end of the installation. It reads “Unable to execute file: C:\Program Files\Carbide\bin\vcredist_x86.exe”

Has anyone else seen this error? The installation completed and I can run the program but my Nomad hasn’t arrived yet so I’m not sure if the install is functional.

There are also reports of the new version not installing on x64: http://www.shapeoko.com/forum/viewtopic.php?f=6&t=7013

as well as a request for a link to the previous version 2 for a reinstall.

If anyone needs a previous V2 this is the copy I have: https://dl.dropboxusercontent.com/u/40862332/CarbideMotion-Setup_old.exe

I really wish people would put the version number in the setup file name…

Is there a mechanism for being notified when a new CM build is released?

Version number isn’t in file properties either…

Randy

The version is shown in the bottom-left corner of the app window

Will, it’s wanting to know the version the installer will install before actually doing the installation…

2.0.333 (the Oct. 14 release, it turns out) installed and launches successfully on 64-bit Win7.

Randy

Another report from the other forum: Shapeoko CNC Router, Rigid, Accurate, Reliable, and Affordable

Everything about the install worked for me except for updating the driver. I’m on Windows 10 x64.

When I try to install the driver from C:\Program Files (x86)\Carbide\driver\carbide.inf, I get an error message saying “The hash for the file is not present in the specified catalog file. The file is likely corrupt or the victim of tampering”. Hope this helps debugging the issue.

Yup. I would have added it if I knew what it was.

Wasn’t pointing fingers at you @dr_g.

Meant as a hint to Carbide3D

The most recent one I just downloaded was 2.0.333. You can see the version number on the bottom left of the startup screen, and on the right it might say Updates Available if there are any. The link is wrong though, goes to /download but should be /downloads.

I just downloaded Carbide motion 2.0.333

Are there any release notes? How do we know what is new/fixed?

The web page link for updates in the old carbide motion software is incorrect.

It would be good to have the current version number shown on the web download page, it is nice to know you are getting the right thing.

I am going to take it for a test drive and see what it does…

When I start carbide motion it homes then measures the tool.

I then set the zero, load the program and start the program

CM then asks me to load a tool, I usually just use the tool that is already set up.

I clock ‘continue without homing’ and it measures the tool again, then starts cutting.

Is there a way to just measure the tool once per job? Most of the time I use a single tool and load it up before starting Carbide motion. When using the machine this way I do not see a need to measure the tool twice, what am I missing?

.

I asked Rob about this a while back. He said that at each tool called for (including the first one) Carbide Motion will measure the “new” tool. I agree that is the safe way to go. It also allows for things like using a 1/8" dowel pin, or even a wide “elephant foot” tool to do the initial Z touching off, which could be an advantage on low-density workpieces, where it might be too easy to dig in the sharp flutes of a cutter when touching off.

That said, it would be nice to have a “skip re-measuring” button as well as the recently-added “skip re-homing” button. I’d use it myself.

Randy

Thanks for the feedback.

Having been in the hardware and software businesses, I understand that

everyone wants a special feature, and it is not practical to do them all. That being said,

I think that a lot of simple projects do not require a tool change and it would speed things

up to have a button that allowed you to skip one of the tool measurements if you are using the same tool for the whole project… Of course if someone did change tools and skipped the measurement, then they may have a real problem… Always a trade off.

BTW Randy, I appreciate all the practical information you have shared on this board, it really

helps. Are you in the CNC business or do you just have a lot of experience building your own things?

.

@3dsteve, you’re welcome, and I appreciate your appreciation.  I’m a mechanical engineer for 35 years, mostly in biotech and scientific equipment, but my CNC is strictly hobby. I’ve been doing CNC since DOS days (CNC Pro and TurboCNC) but my first exposure to gcode predates that by years. In 1989 I wrote some Basic programs on a Mac+ for 4-axis wire EDM cutting of a mold for a test-tube holding rack that included mold draft angles, for a moldmaker we were working with.

I’m a mechanical engineer for 35 years, mostly in biotech and scientific equipment, but my CNC is strictly hobby. I’ve been doing CNC since DOS days (CNC Pro and TurboCNC) but my first exposure to gcode predates that by years. In 1989 I wrote some Basic programs on a Mac+ for 4-axis wire EDM cutting of a mold for a test-tube holding rack that included mold draft angles, for a moldmaker we were working with.

Links on my website to my (other than Nomad) former and current CNC machines are

http://www.prototrains.com/shermill/shermill.html

http://www.prototrains.com/sherlathe/sherlathe.html

http://www.prototrains.com/gantry/gantry.html

http://www.prototrains.com/tormach/tormach.html

http://www.prototrains.com/feeler/feeler.html

I have extreme admiration for Rob, Jorge, Edward, Apollo and crew for the work they’re doing on the Nomad, and of course Rob for MeshCAM, which I’ve been using since the early betas in 2003.

Randy