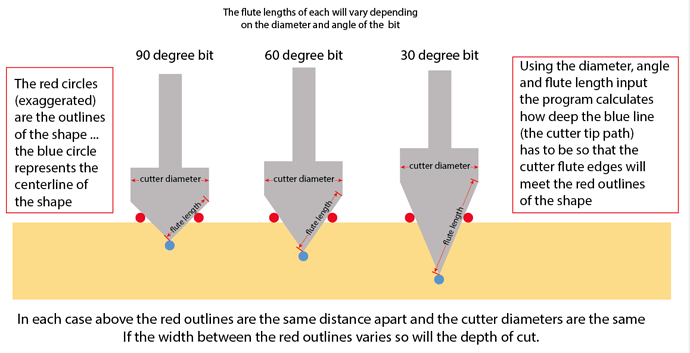

Yes F-engrave does work well but CC does a good job also. It’s important to understand what’s going on with any V carving program and operation. Here’s another sketch to consider. It’s snowing here today so I’m on a drawing roll rather than working

11 Likes