There were a few threads here about how straight bits are just…not necessarily our friends on a desktop CNC. I’m sure @LiamN will voice this much better than I ever could, having used straight bit like this one.

There are two main likely reasons for this:

- losing steps on the motor for that axis. This happens when the forces the tool/router has to fight to move through the material exceed that max torque/force that the stepper motor can deliver. So the motor “skips” steps, and since there is no way for the Shapeoko controller to know that this happened, it will continue to drive the motor normally as if nothing happened…resulting in the rest of the cut proceeding normally but…in a different location from where it should have been. This is remedied by using less aggressive feeds and speeds/depth of cut.

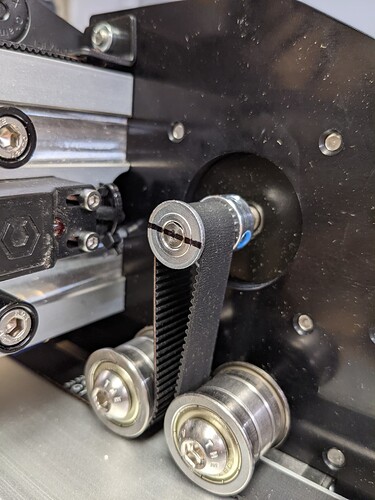

- the stepper motor pulley slipping on the shaft, if the setscrews on the pulley are not tight or the pulley is not positioned correctly on the shaft (there must be one of the two set screws aligned to the flat on the motor shaft). Sometimes the setscrews are not quite tight enough, so the pulley does not slip under a low cutting load, but will slip under heavy load. The easiest way to check this is the marker trick: draw a line across the pulley and shaft. Next time the offset cut problem happens, check the marker line. If it’s not aligned anymore…the pulley has slipped at some point.