Well just been talking to a guy who wants to sell me everything to add to my Shapeoko XL…

His main line was… “do you have a Charge Pump?”

New electrical Laws throughout the UK and EU say I should have one! Having bean a sales person for over 40yrs …That’s a cracker.

I don’t think I need one BUT… I’m putting out to everyone

What is it?

What does it do?

How does it work?

Why do I need one?

This I hope is a great forum question

It’s a safety device that cuts power if the control board locks up. Basically with Mach3 (which is meant for big boy CNCs) it can generate a steady pulse signal on one of it’s pins. If Mach3 locks up this signal stops. The charge pump sees this lack of signal and cuts power. They are not a bad idea, but I do not think the Carbide Motion Board supports it.

Hi CthulhuLabs, Thank you for that… come to think about it the company sells Mach3…

Hmm,

To me a charge pump is a simple DC to DC voltage converter circuit, anyway, there’s a huge difference in what safety legislation applies between what you do in your shed and what you might be legally responsible for somebody doing a place of work governed by the elf-n-safety at work act as an employer.

Hi Liam, Hope your well… Thank you for the advice… Tink

NP, Doing OK, weather has gone a bit Yorkshire down here

If you’re just using a regular Shapeoko and not a VFD powered AC spindle then all your electrics are packaged, CE approved units powering the Shapeoko and whatever computer you’re using so reasonable care with the power tool is all that’s really left, don’t leave it unattended with children or pets. Regulatory compliance was dealt with for you by Carbide3D on the electrical front.

If you’re not doing fixed installation wiring and you’re on the other side of a plug & socket and you’re not the employer there’s much less regulation that impacts you.

This will all vary by which country you’re in of course, this is pretty UK specific.

I have bought a 1.5Kw and VFD kit from G-Penny and it works… which is good … I have had the new HDZ delivered from Carbide and fitted it BUT with a Makita as I have some work to finish… Panic is a little on my mind as to fit the new spindle… but will get around to it… No Kids or pets just me and the shed… I will have to make the enclosure a lot higher though

Took me a little while to get around to actually fitting and plumbing the spindle too, the HDZ is just a great little piece of engineering.

As for vertical height, if the spindle is water cooled you can put 90 degree elbows in those pipes to keep the height down and the bend issue on the spindle power cable is about where it repeatedly flexes, you can have a fair bend straight off the connector, so long as it’s held there and not constantly moving to be stressed. I found the dust extraction was my main height constraint and settled on not getting around to the enclosure on top of the bench which solved all those problems in one neat prevarication.

Given the experiences of some others with the Chinese spindles, I’d suggest checking that pin 4 is really connected to the shell of the spindle, make sure the earth goes properly through the VFD to the spindle, even with an RCD somewhere in the supply, you can still get a serious zap as the VFD stores up power in it’s DC stage so we’re back to relying on proper earthing for safet.

Thanks for the heads up… when I got it I did check visually (took the screws out at the top) and tested with my tester and all is good… great idea for the 90 degree elbows … where did you get them from?? have you got any images so I can have a nose??

[quote=“tink07, post:9, topic:23420, full:true”]

Thanks for the heads up… when I got it I did check visually (took the screws out at the top) and tested with my tester and all is good… great idea for the 90 degree elbows … where did you get them from?? have you got any images so I can have a nose?? [/quote]

Ah, somewhat more complete on the enclosure effort than me then

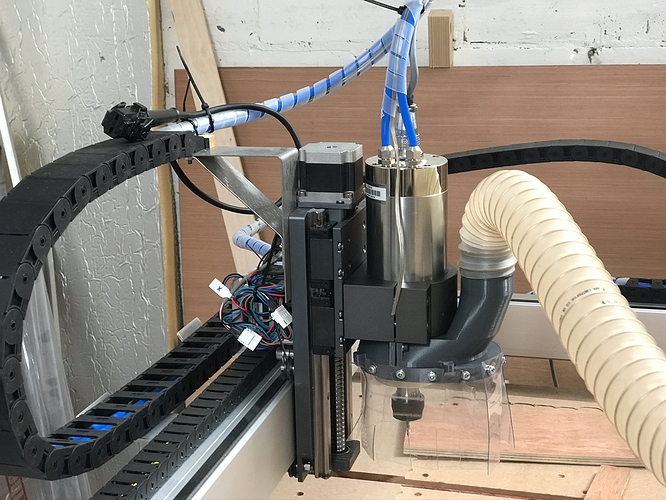

Mine just has the hoses and cable coming out into spiral wrap and then a separate drag chain to avoid having to mess about the original Shapeoko wiring and minimise the interference risks.

I’d suggest something like this as the hose elbow.

The trick is figuring out how to get the cable and hose from the top of the spindle to whatever mounting point you go back to, either the drag chains or enclosure without creating pinch or wear flex points.

This is my extra drag chain & spiral wrap approach to get the spindle power & plumbing up to the HDZ, I brought the extra drag chain up much higher on the Z carriage to keep the bend radius nice and wide for the pipework;

The other power cable is from the old Kress router.

Great Thank you… I will get on to that when I start the upgrade this week… don’t have any dust shoes yet as I don’t have a 3d printer … and won’t buy one until I know what to do next… I like the grey one!

Thank you for the help … keep in touch… Tink

NP,

By the way, if you didn’t source drag chain yet, I got these for £10 each which were more than big enough.

Bookmarked both products and will order them tommoz Thanks again for your help

This topic was automatically closed after 30 days. New replies are no longer allowed.