Hi @vees19,

First and foremost, make sure to contact support@carbide3d.com about this.

Now, this could be a number of things, but you should be able to check a few possible causes:

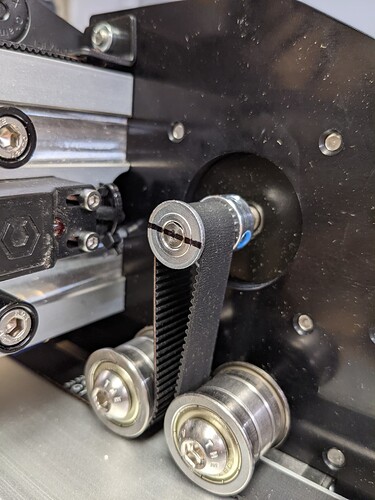

- it could be a loose of damaged belt. Inspect your X belt and Y belts ?

- it could be a loose or damaged v-wheel (from the earlier crash). Go back and inspect every single v-wheel, for flats, cracks, or spinning loose.

- also related to the v-wheels: with the machine turned on (but router off and unplugged), if you grab the tip of the router and wiggle it around (front/back, left/right), can you feel any significant play ?

- it could be a semi-loose pulley on one of the stepper motors. Use a marker to draw a line across the pulley and motor shaft, run your job, come back and check if everything is still aligned or if the pulley slipped with respect to the shaft

- it could be that the machine got thrown out of square: with the machine turned off, manually moving the gantry very slowly to the front and to the back, do the left and right sides contact the front/back plates at around the same time ? Is there a significant gap on one side upon contact ?

My guess would be something to do with the v-wheels, but we’ll see.