This with some Carbide Green resin fill would look sharp on 4 corners of a Shapeoko Bench…

I really didnt have one in mind to be honest, but after I started to model it, I am thinking of making a new table for my XL and I think this would look good on the corners and be stronger than simple butt joints.

If anyone wants an idea for this challenge pm me I’ve got a doozie. You’ll need someway to vertically hold the work piece tho.

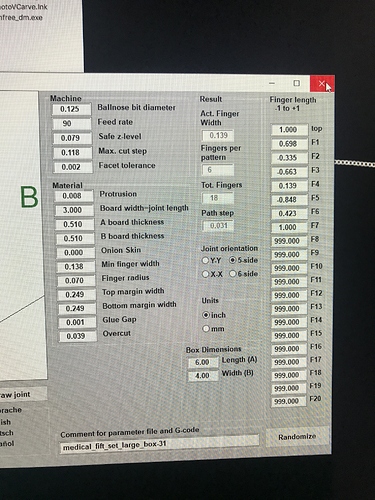

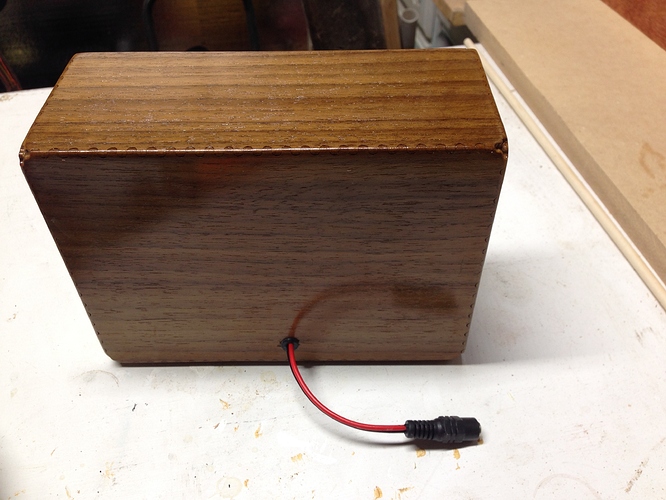

Here is a lighted shelf i made for over my desk. Its made from just some cheap scrap i had. The program i used was called Fingermaker. I looked for the link to it but i guess the programmer discontinued it. it was done with a 1/8" ball mill.

and here is some more of other projects.

Here is the legs i did for the Grand Lake table.

Sorry i don’t have a project file as it just output G-Code.

This is a test piece I made today, not a finished project, but I hope it still qualifies…

My goal is to make a table base like this:

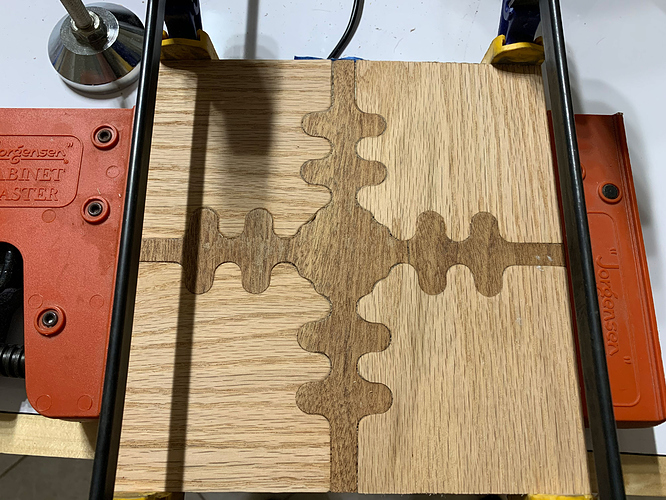

Saw this challenge and thought I’d try to come up with a different joint, that would help with clamping and glueing the two leg pieces. Got some inspiration from those excellent joints shared on the links above. This was my first test:

I was surprised how well it fit on my first try, though still some improvements would need to be made.!

Quite stylish. Then again, I am a fan of midcentury modern.

One week to go!

I hope everyone is safe, and busy in the shop.

I’m stuck in the “Don’t have any more birch plywood, but don’t want to go out except for the once weekly shopping trip.” conundrum.

Which I can perfectly understand, I do the same (single short trip to get food once a week, period)

If you guys want to submit a “design only” if you cannot actually cut it, that’s fine with me.

Bump! 3 days left.

I’m afraid the theme wasn’t quite as inspiring as I thought it would be, mmh.

Fewer participants = higher chances to win something, just saying !

I will try to put something together before the deadline that would be worthy of consideration. Not so much for the prizes, which are awesome btw, but to show my support by participating in these amazing contests that I appreciate so much. Hope everyone is well, please be safe!

In terms of work holding, this new Shaper Workstation may be a good source of inspiration, as they seem to have come up with some interesting solutions to common problems:

Not promoting this tool, by the way, just the design of the workstation seems pretty well thought out.

It’s a great theme Julien! I suspect some folks are dealing wit the major interruption to their routines and still making that adjustment. Others (ahem) may have made the project difficulty right up to their limitations and it’s taking more time then expected to complete

Yeah, the Shaper Origin is interesting — though apparently they monetize their support? One has to pay extra to get the sort of specific help with projects which we provide even to folks using the free edition of Carbide Create on 3rd party machines (though I guess one should expect that sort of thing when Autodesk is in the mix) — I actually linked a thread discussing reasons folks had sold their Shaper Origins in our team chat (there are times I feel like Stephen King/Richard Bachman discussing this stuff).

No sorry, I didn’t mean the shaper origin - it’s a fun toy but frankly I don’t understand the point of a $2400 CNC machine where you have to be the gantry. I meant the new workstation thing they are pre-selling. I bet you could take some of the ideas in their design and make good use of them for vertical work holding on a Shapeoko.

Actually mentioned that on the team chat as well — at some point, I’m going to finish working through my backlog of joinery designs and projects and eventually will be revisiting:

which I’d like to remake in a version using a Hirth Coupling for positive angular locking at some number of degrees (radians?) which makes sense.

Hello fellow C3D fans!

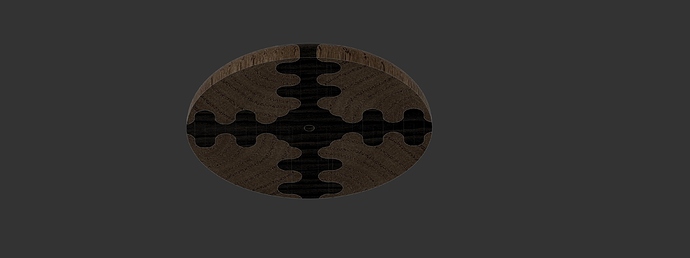

I am beginning another CNC contest marathon lol, at the last minute I decided to go for it and with some very helpful advice, was able to come up with what I think is a decent design representing joinery, art, and a tribute to C3D at the same time.

I try to create intriguing objects that are unique, look good on a desk and use contrasting materials, and throwing in a bearing never hurts!

Looks like I might be able to get most of it done by the deadline if I go straight through to the end, who needs sleep! Or not… lol… zZZzzZzz

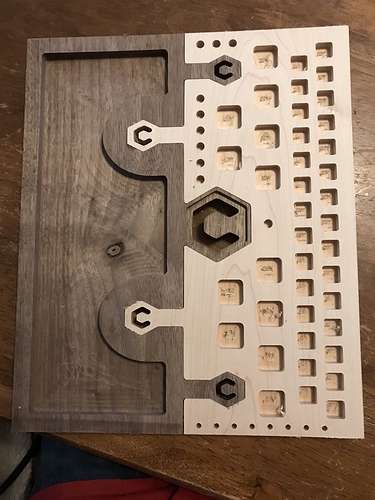

My first joinery project, will see how it goes! Check for updated pics on this reply as I progress.

After about 24 hours of machine time, things are going pretty well, a few mistakes were made…

My joinery fingers were kind of big, but fit my router bit to perfection, making cleanup on the bottom edges and tabs really easy.

I got dumb again and designed aluminum parts that need 2 mm end mills and multiple tool changes… Worked out fine though with a Carbide 3D bit #282-Z and a #112-Z.

Broke one of the spokes off my center joinery piece, no big deal glued it back on… Got 2 of my pieces backwards and did not notice the grains did not match until it was too late. Gorilla wood glue sets really fast!

Oh and I designed my joinery center part 1 inch too long to use the black walnut I had in stock so I used a piece of my mystery wood which is a funny story…

I was in a small local woodshop buying stock and I see these sections of really perfect dark reddish wood 1 inch thick no warp being prepped for another customer…

Me: Can I get some of that? Is it hardwood?

Woodguy: Yes and it is cheaper then Walnut.

Me: Can I get 8 feet in 18 inch sections please? Whats it called??

*Guy in background fires up a table saw RAAAAWWAAAAAAA

Woodguy: SURE ITS FEWIANSHAW@#$FDA

Me: HUH? WHAT?

Saw: RAAAAWAAAAAA

Woodguy: IT’S GLAWDWIDNWSHAWDDDERR

Me: I’LL TAKE IT!

Mills great, beautiful stock almost perfect no warp, no idea what it is. Pic below.

Progress pics:

Wow what a journey this one was! Very happy with the results! I think in the future I will hold off on the Marathon builds though haha… zZZZzzZzzz

Hey Will, I have seen you link to that fixture for cutting vertical joint several times and just about every time I click the link to see how it works. But with the one picture I haven’t managed to grasp the concept…would you mind posting more pictures?

Plan to make one sometime and need ideas!

Hello Everyone,

This is my first post and contest to C3D, so hopefully I get it right,

but I have seen the contest for awhile and figured since I have the time now why not. Besides I needed a tool and bit holder anyway and since that was my next thing on my list to make, why not give it a go, nothing special just something simple.

left side joinery.c2d (743.1 KB)

right side joinery.c2d (868.3 KB)