I run a Hyundai Silent oil free air compressor that is produced and sold under many brands. This particular model makes 135 l/min at 8 bar and has a 24 l tank.

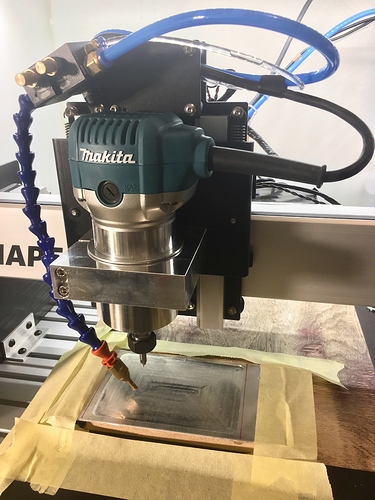

At the business end of the Shapeoko I have this setup:

I use for engraving 1bar, for milling about 2-2,5 bar plus ethanol if necessary. With these settings and the nozzle relatively close to the end mill I have great results but the compressor works more than it should. I decided to actively cool it with a blower fan to keep it cold.

If the only reason is to invest in a compressor is to clear chips than you have better solutions. (Bit fan or dust shoe)