Hi Carbide guys,

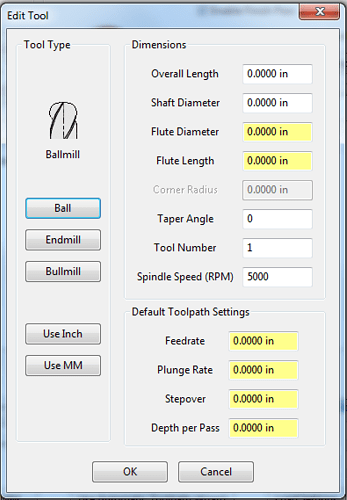

Can someone please direct me to the correct settings in MeshCAM for defining the new cutters I just got from Carbide? I now have the 111 & 112, but don’t know what to put in the Edit Tool parameters.

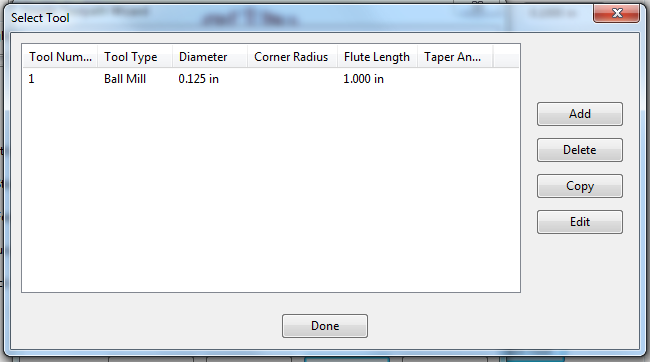

How odd, it looks like they show up as options when you run the Carbide Auto Toolpath, but then if you try to change the tools in the Review Toolpath Parameters screen, e.g. so that you can set it to use a different tool for the finishing pass etc, they do not appear as options.

Oh, wait, actually it looks like they are now added. I had to run the Auto Toolpath and select the 111 as my cutter, and then run it again and select the 112, and now they seem to have been added to the list of tools that appear when I click Select Tool on the Parameters screen. Strange…

Hi Mr. Hume,

The settings are going to vary based on both cutter and material for any given job. The goal is to get the right chip-load and surface-speed (if possible) for the cutter & material combo: so for example a carbide cutter vs. a HSS cutter will be different, and will require different settings depending on whether you’re cutting brass, aluminum, machining wax, or renshape, etc… Also, if you’re roughing you’re looking to take more material out with less of a concern for surface-finish, so you’ll lean toward the more “aggressive” end of the chip-load range than if you’re doing a finish operation where you want to create a pretty result more than you’re worried about speed of material removal, so you’ll take a lower chip-load to get a smoother surface.

The two variables that you use to get to the desired chip-load are your feed-rate and spindle-speed, so you adjust both to get to the desired chip-load within the machine’s limitations.

I’d suggest poking around and seeing some of the other “feeds and speeds” conversations on the forum, and checking out some of the resources available for calculating the right values for each job.

I am also having the same problem. Toolpath wizard only gives me one option.

Is there an update I am missing? I will gladly import all the info for the cutters we received using “add tool” if I receive the data regarding

I have yet to cut anything other than the wrench. I am a major newbie spending time learning sketchup etc to create files to import.